BOLD AUTOMATION. HUMAN IMPACT.

Engineering Your Edge, Together

Part Marking SOULTIONS FOR

LIFE SCIENCE AUTOMATION

Ensure tracebility, complaiance, and product integrity from start to finish

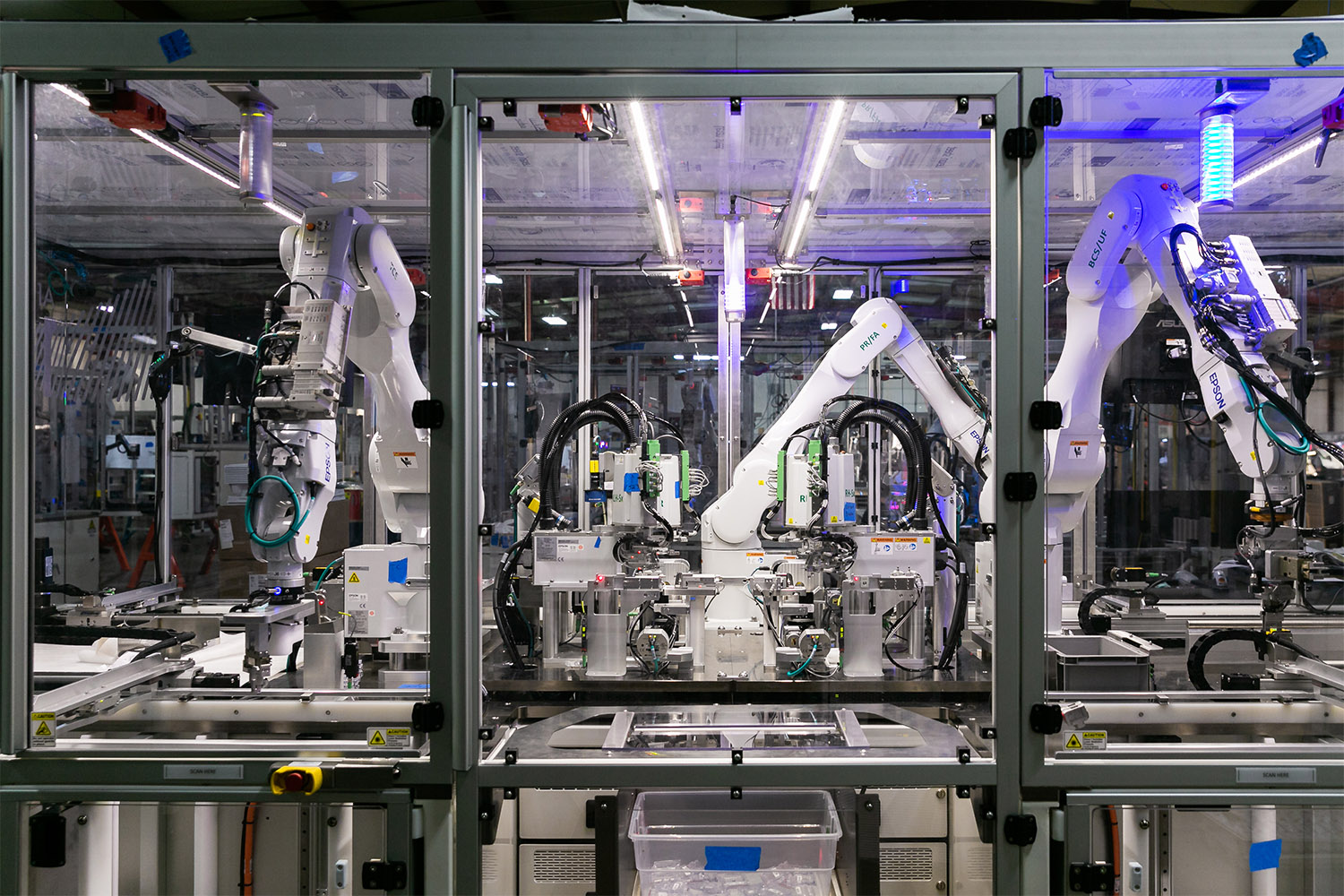

Traceability is mission-critical in the life sciences. Whether you’re producing diagnostic kits, implantables, or wearables, every component must be identified, verified, and traceable to meet regulatory standards and patient safety requirements.

Automation NTH engineers and integrates part marking systems directly into your automated equipment to streamline serialization, ensure cleanroom compatibility, and future-proof your data tracking infrastructure.

BOLD AUTOMATION. HUMAN IMPACT.

Engineering Your Edge, Together

laser marking

Permanent, Cleanroom-Safe Marking for High-Reliability Applications

Laser marking uses focused light to etch or ablate information directly onto a part’s surface—no labels, inks, or moving mechanical printheads required. It’s ideal for medical devices and diagnostics where durability, legibility, and cleanliness are paramount.

Key Advantages:

- Permanent and Tamper-Proof: Won’t smear, fade, or rub off, critical for lifetime traceability.

- Cleanroom-Friendly: No inks, solvents, or consumables, laser marking generates minimal particulate and can be paired with filtration.

- Highly Versatile: Works on metals, polymers, clear materials, and even curved or textured surfaces.

- Software-Driven: Easily update markings (e.g., serial numbers, lot codes) via control system interfaces.

How NTH Does It:

- We commonly integrate laser markers for their speed and flexibility.

- Air filtration systems are included to extract vapors or particulates at the source.

- Our laser safety experts implement custom guarding, including laser-safe Lexan or metal enclosures.

- Parameter control is embedded in the HMI, eliminating the need for external laptops or licenses to make changes.

Common Use Cases:

- Etching data matrix codes on diagnostic PCBs

- Human-readable marking on wearable devices

- Marking plastic housings and enclosures

- Marking surgical instruments for traceability

Inkjet Marking

Flexible, High-Speed Printing for Variable Data Applications

Inkjet printing is a non-contact method that sprays microscopic ink droplets onto parts. This is ideal for dynamic production environments requiring frequent changes to print data or formats.

Key Advantages:

- Fast and Adaptable: Suitable for high-throughput production lines with minimal cycle time impact.

- Supports Various Inks: Solvent-based, UV-curable, water-based, food-grade, and heat-sensitive inks available to match material and sterilization needs.

- Non-Contact Printing: Excellent for marking delicate or oddly shaped surfaces.

- Cost-Effective: Lower initial investment and simpler maintenance compared to laser marking.

How NTH Does It:

- We use inkjet printers and integrate them with vision inspection systems to ensure print quality.

- NTH-developed HMIs consolidate all fault monitoring and ink status into a single interface for operator ease.

- We support multi-format encoding (QR, DataMatrix, alphanumerics) with dynamic changeovers controlled through MES or PLC inputs.

Common Use Cases:

- High-speed barcode marking on medical packaging lines

- On-the-fly serialization for molded plastic components

- Printing expiration dates and regulatory symbols on sterile containers

RFID Tag Embedding

Data-Rich, Contactless Identification for the Smart Factory

RFID (Radio Frequency Identification) allows manufacturers to store and access data directly on the product, without line of sight or precise orientation. RFID tags can be read or written to wirelessly, enabling real-time tracking through the entire product lifecycle.

Key Advantages:

- Line-of-Sight Not Required: Tags can be embedded inside parts or hidden from view.

- Read/Write Capable: Unlike static barcodes, RFID data can be updated throughout manufacturing.

- Compact and Durable: Tags are small enough for micro-device cavities and tough enough for sterilization.

- End-User Integration: Useful for clinicians or patients to access use history, instructions, or expiration dates via a scan.

How NTH Does It:

- Our precision pick-and-place capabilities allow tag embedding during automated assembly.

- RFID readers are integrated with PLC-controlled systems to verify tag content, update product status (e.g., reject/pass), and log results to databases.

- Tags can be password protected or encrypted for regulatory compliance and security.

Common Use Cases:

- Embedding in sterile surgical kits to track contents and last sterilization date

- Smart labeling of medical devices for usage tracking and recall readiness

- Enabling product authentication and instructional access for patients

Thermal Transfer Printing

Reliable, High-Resolution Labeling for Durable, Flexible Identification

Durable, Software-Driven Labeling for Bags, Packaging, and Flexible Surfaces

Thermal transfer printing uses heat to transfer ink from a ribbon onto labels or packaging materials, producing high-resolution, smudge-resistant markings that hold up in demanding environments. It’s especially useful for applications requiring barcodes, serialization, or human-readable information that remains intact over time.

Key Advantages:

• Long-Lasting Print Quality: Resistant to smudging, abrasion, and moisture—ideal for labeling in clean or harsh conditions.

• Versatile Substrate Compatibility: Prints effectively on paper, polypropylene, polyester, vinyl, nylon, and other flexible materials.

• Fast and Durable: Produces consistent, reliable results at high speeds.

• Simple Content Updates: Easily change print data (e.g., lot codes, expiration dates) through software without hardware changes.

How NTH Does It:

• We commonly integrate thermal transfer printers inline to label bags or place labels directly on parts.

• Systems often pair with NTH’s Reel Feeder to automate label handling and placement.

• Vision inspection systems validate print presence and quality in real-time.

• Our user-friendly HMI platforms monitor ribbon status, identify jams, and simplify reloading with minimal operator intervention.

Common Use Cases:

• Labeling bags containing diagnostic assemblies, such as on the Hamilton Flow Tube Assembly project.

• Packaging-level serialization or barcode labeling for medical disposables.

• Adding human-readable lot codes or logos to products where inkjet or laser are not viable.

Choosing the Right Part Marking Method

Capability | Best For | Speed | Durability | Consumables |

Laser | Cleanroom/Perm Marking | High | Excellent | None |

Inkjet | High-Speed & Low Upfront Cost | Very High | Moderate | Low |

RFID | Contactless Data Storage | High | Excellent | None |

Thermal Transfer | Labels/Packaging | Moderate | High | Moderate |

Let’s Build the Right Marking Solution for You

Whether you’re tracking a single-use diagnostic or managing a reusable medical device, we’ll help you implement a smart, compliant, and scalable marking system tailored to your product, workflow, and regulatory needs.