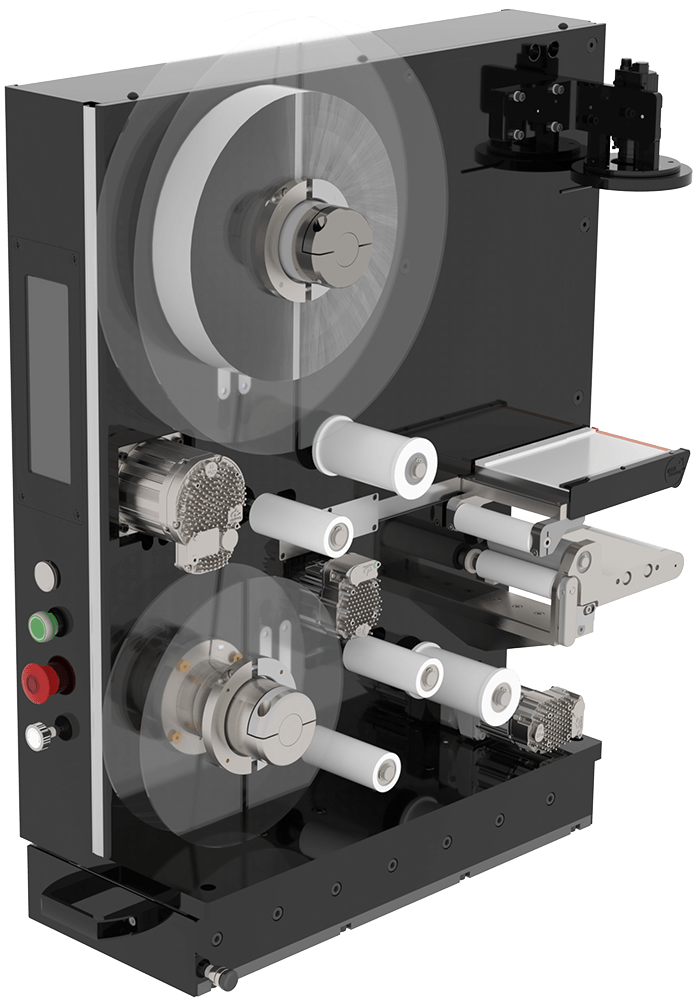

Advanced Web Handling for Medical Device Automation

At Automation NTH, we’ve combined decades of experience with off‑the‑shelf reel feeders and cutting-edge assembly expertise to deliver a superior solution. The NTH Reel Feeder improves upon conventional systems by prioritizing intuitive operation, seamless integration, and sensorless precision for continuous, hands-free performance.

Automation NTH proudly introduces the NTH Reel Feeder—a revolutionary leap in precision web handling tailored for reel-fed assembly and labeling applications in the Life Sciences industry.

Engineered as a stand-alone system, the NTH Reel Feeder seamlessly integrates into existing automation equipment, offering unmatched accuracy, ease of use, and operator autonomy.

Key Features of the NTH Reel Feeder

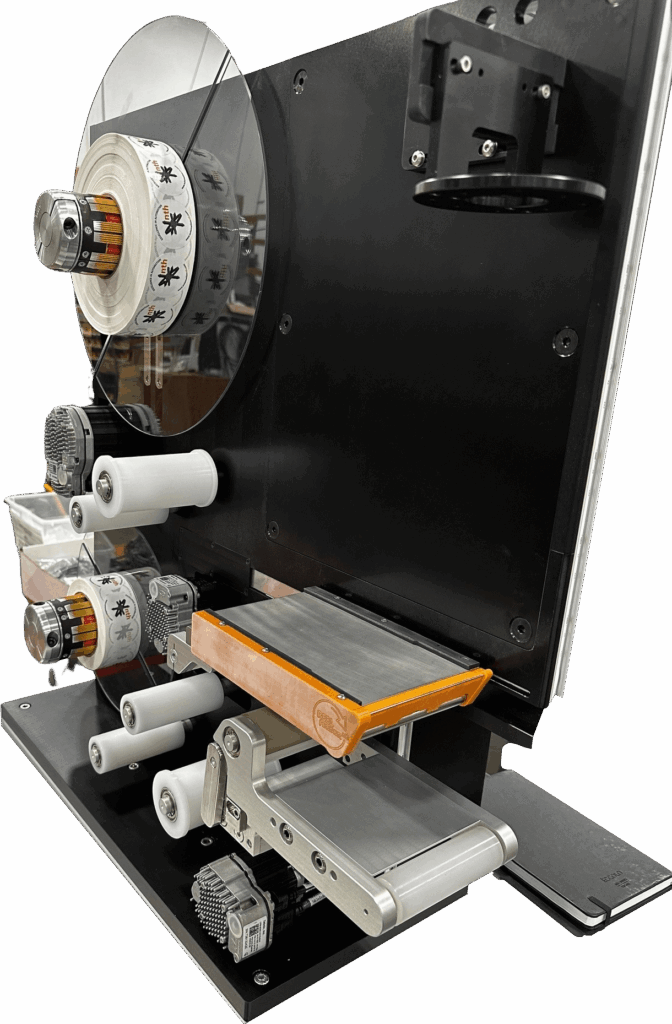

Compact Design

- Stand-alone unit with a bookshelf orientation for side-by-side mounting.

- Effortless roll changes with easy operator access and full web access.

Sensorless Registration

- Automatic roll diameter calculations for consistent performance.

- Vision-guided edge detection and registration eliminate manual adjustments.

Accurate Operation

- Servo-driven web handling ensures precise position feedback and continuous web tracking compensation.

- Vision-guided pick location for reliable operation.

Seamless Integration

- Built for easy incorporation into assembly equipment.

- Open Ethernet communication for operation, fault reporting, and system messaging.

- Integrator plate allows for flexible field add-ons and I/O handshaking ensures safety.

Performance Specifications

- Index Speed: Up to 600mm/sec (23.6in/sec).

- Index Precision: Down to ±30 µm.

- Web Width: 25-102 mm (1-4 in).

- Core ID: 76.2 mm (3.0 in).

- Unwind Roll OD: Up to 407 mm (16.0 in).

- Rewind Roll OD: Up to 267 mm (10.5 in).

Advantages at a Glance

- Low-friction peeler bar for smooth operation.

- Intuitive web path with easy access.

- No manual adjustments required for seamless functionality.

- Adaptive, sensorless web control for continuous performance.

- Rejected labels are removed automatically from the web.

Dimensions & Utilities

- Power: 110 VAC, 1-Phase, 50/60 Hz, 10 Amps.

- Air: 80 PSI clean and dry.

- Communication: Ethernet TCP/IP.

ACCESS OUR EXPERTISE

Let’s begin discussing how the NTH Reel Feeder can be integrated into your automation lines!

Automation NTH

We Turn Automation into Your Competitive Advantage!

Increase Production Capacity

Improve Product Quality

Enable Operator Autonomy