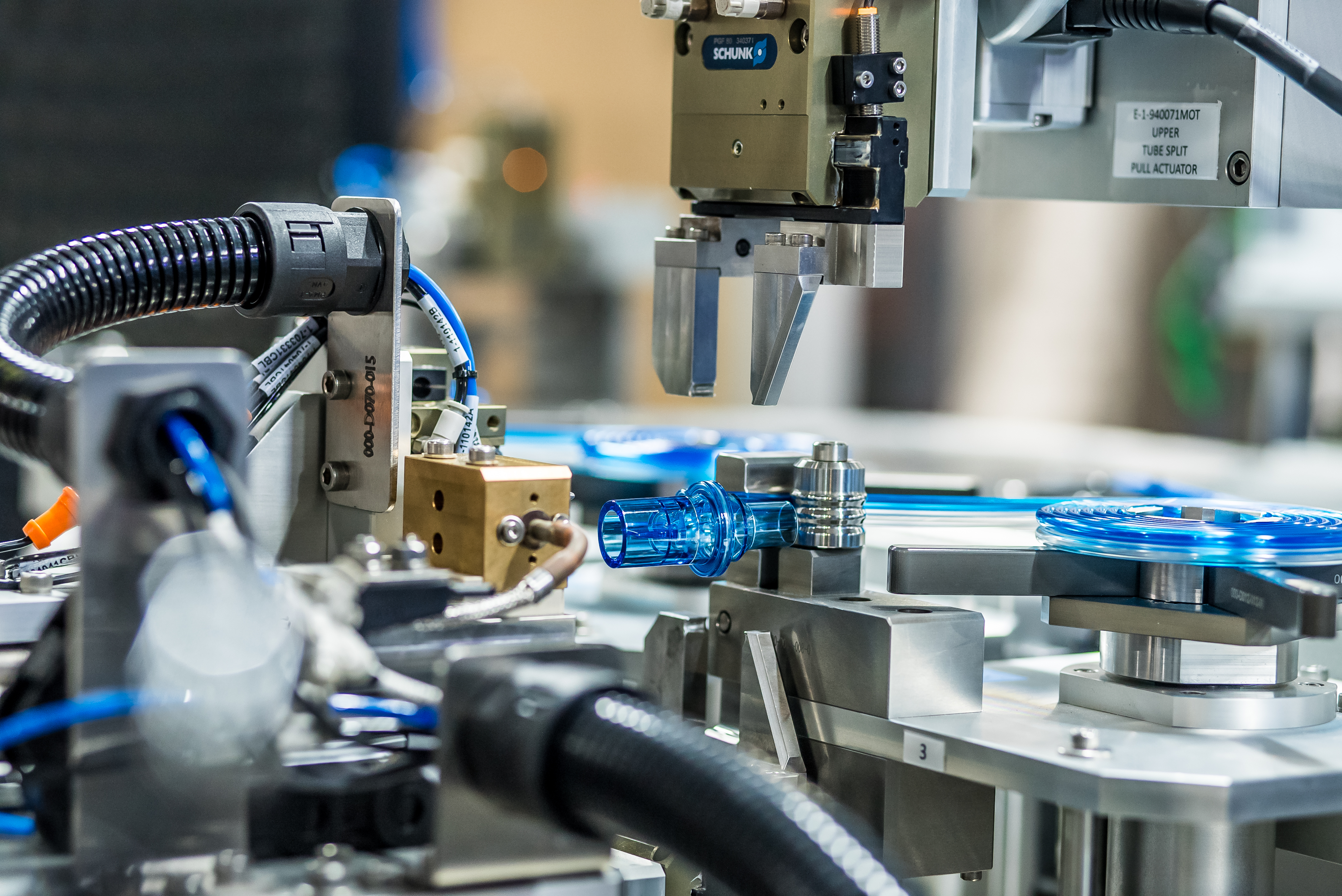

Life Science and Medical Device Automation

Markets we serve

Automation NTH helps life science and medical device manufacturers achieve reliable, efficient production at scale. Whether transitioning from manual processes or scaling existing automation, the challenges of labor availability, quality assurance, and speed to market directly impact manufacturer’s ability to meet production demand.

Life science and medical device manufacturers consistently tell us about their key operational hurdles:

- Quality challenges that increase scrap rates and compliance risks

- Labor-intensive manual processes that limit production capacity

- Production delays and downtime that threaten market opportunities

- Difficulty maintaining output with workforce shortages

- Complex processes that are hard to validate and scale

Automation NTH focuses on supporting Life Science and Medical Device manufacturers across many complex products including:

Medical Device

We help medical device manufactures overcome complex automation challenges-delivering systems that ensure precision, efficiency, and regulatory compliance at every step of your production process.

- Surgical Staplers & Tools

- Laparoscopic & Endoscopic

- Ablation Technologies

- Vascular Technologies

- Catheters

- Guidewires

- Stents

Medical Diagnostics

We automate critical processes for Molecular Diagnostics, In Vitro Diagnostics (IVD), and Genomic Testing Systems. Our solutions include precise reagent dispensing (including Lyophilized beads), assembly, capping, and inspection utilizing environmentally controlled processes with comprehensive quality verification.

- Microfluid Discs and Chips

- Cartridges

- Cassettes

- Vials

- Lateral Flow Strips

- Support Packs

- Point of Care

Drug Delivery Systems

We automate the assembly and handling of Drug Delivery Devices. Our solutions include assembly, inspection, labeling, testing, and packaging designed for clean room production environments.

- Autoinjectors

- Prefilled Syringes

- Patch Pumps

- Smart Injection Devices

- Inhalers

- Nebulizers

- Transdermal Patches

Wearable Devices

We automate the assembly and handling of Wearable Devices. Our solutions integrate electronics assembly, wireless validation, inspection, and environmental protection testing designed for cleanroom production environments.

- On-Body Pumps

- On-Body Monitoring Devices

- Therapeutic Patches

- Connected Health Devices

- Cardiac monitors

At Automation NTH, we don’t just provide automation equipment — we deliver the tools, expertise, and support you need to solve your production challenges with greater precision, higher confidence, and faster results. Let us be the partner that drives your success forward.

A Practical Path to Automation

Our approach helps you succeed at each step:

Automation Consultation

We start by understanding your current processes, production goals, and quality requirements.

Proof of Principle Creation

For new and complex processes, we develop proof of principle systems that validate key manufacturing steps before implementing full automation.

Scalable Production

We expand capacity as you grow, from semi-manual work cells to fully-automated production lines.

Put Bold Ideas Into Motion

Automation NTH

We Turn Automation into Your Competitive Advantage!

Increase Production Capacity

Improve Product Quality

Enable Operator Autonomy

The Guide to

Successful Automated Manufacturing

Download our comprehensive guide to learn more about how to create a successful automated manufacturing system for your organization.