Beyond Our Walls: How Automation NTH Customers Can Drive Success with Data-Driven Gemba Walks

Driven by a commitment to “excellence in automation,” we continuously refine our approach to project execution to deliver maximum value to our customers.

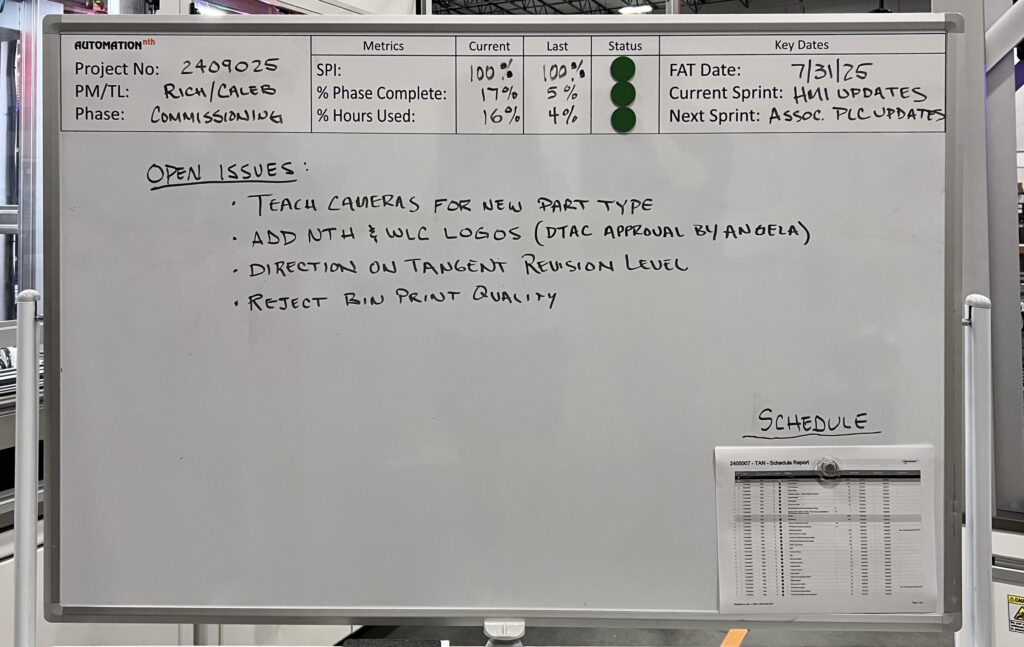

A cornerstone of this refinement is our evolved use of Gemba Walks, a Lean methodology practice that empowers leaders to go to the actual place where work happens, observe processes, engage with team members, and identify opportunities for improvement.

Traditionally about observation and learning, we’ve amplified the power of Gemba Walks by incorporating data-driven insights and incremental goal setting into our daily operations. This shift allows us to not only pinpoint inefficiencies but also take proactive steps to address issues and optimize performance in real time.

The principles behind our successful Gemba Walk strategy are equally applicable and beneficial for our customers in their own facilities. Imagine the impact of applying these methods to your manufacturing processes, your operational workflows, or even your internal project management.

Infusing Data into Your Gemba Walks: What You Can Measure, You Can Improve

As Peter Drucker wisely noted, “you can only improve what you can measure”. By integrating real-time operational data into your Gemba Walks, you can make more informed decisions and track progress more effectively. Here’s how you can enhance this process within your own organization:

- Tracking Key Performance Indicators (KPIs): Just as we monitor cycle time, bottlenecks, and resource utilization, you can identify critical KPIs relevant to your production lines, assembly processes, or service delivery. By observing these metrics directly on the Gemba Walk, you gain immediate, unfiltered insights into performance.

- Aligning Small, Incremental Goals: Large-scale improvements can feel daunting. By breaking down your major operational goals into smaller, manageable objectives, you can drive steady progress and avoid reactive “firefighting”. Use your Gemba Walks to check on the progress of these micro-goals and celebrate small victories.

- Enhancing Visibility on Resource Utilization vs. Forecasts: Whether it’s raw materials, machine uptime, or labor hours, understanding how actual usage compares to estimates in real time is crucial. Implement tools and processes that allow your teams to see this comparison, helping them stay on track and manage resources more efficiently on the shop floor or in the office.

Improving Operational Visibility Across Your Teams

Transparency in performance tracking is an ongoing initiative for us, and it should be for you too. Better visibility empowers your teams to make smarter decisions and adjust workloads proactively. Consider these strategies for your facility:

- Implementing More Accessible Reporting Tools: Provide clear, intuitive dashboards that highlight actual versus forecasted performance. When your teams can easily access and understand this data, they can self-manage their efficiency and identify issues before they escalate.

- Encouraging Team Accountability: Empower your teams with the data relevant to their area of responsibility. When they see how their actions impact overall operational goals, they are more likely to take ownership and strive for alignment.

- Enhancing Communication Across Departments: Break down silos. Ensure that production, maintenance, quality, and management are all in sync with operational realities. This prevents surprises and allows for collaborative problem-solving.

By combining the power of direct observation through Gemba Walks with real-time data insights and the discipline of incremental goal setting, you can significantly strengthen your ability to deliver successful outcomes, whether that’s increased production, improved quality, or enhanced customer satisfaction.

We believe continuous improvement is a team effort. We encourage our customers to embrace these powerful methodologies within their own operations. By making every step count, together, we can provide excellence in automation and beyond.