Automation NTH has developed solutions to better serve our customers by enabling fast, flexible automation and the ability to optimize machine performance through analytics

The FLEXBASE platform enables manufacturers to rapidly deploy validated work cells across a variety of applications. The cells can be integrated together using conveyors to create an entire production line. FLEXBASE is designed to be highly configurable and utilize IIoT capabilities such as Automation NTH ’s OEE Optimizer® Suite. FLEXBASE can be used for manual, semi-automated, or fully-automated processes.

Automation NTH proudly introduces the LyoFeeder, a next-generation automated lyophilized bead feeder designed for high-precision bead handling in pharmaceutical, diagnostics, and life sciences manufacturing. Built on years of automation expertise, the LyoFeeder advances conventional bead handling by combining gentle handling, vision inspection, recipe control, and seamless PLC integration for hands-free, repeatable performance.

The LyoFeeder integrates into new and existing automation equipment, delivering accuracy, speed, and reliability where precision placement matters most.

At Automation NTH, we’ve combined decades of experience with off‑the‑shelf reel feeders and cutting-edge assembly expertise to deliver a superior solution. The NTH Reel Feeder improves upon conventional systems by prioritizing intuitive operation, seamless integration, and sensorless precision for continuous, hands-free performance.

Automation NTH proudly introduces the NTH Reel Feeder, a revolutionary leap in precision web handling tailored for reel-fed assembly and labeling applications in the Life Sciences industry.

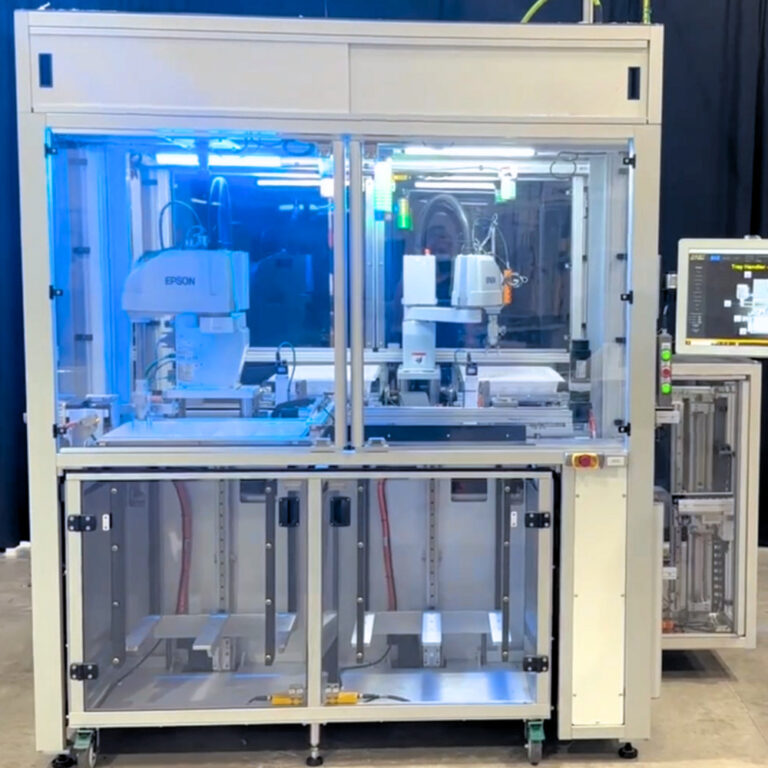

The Automation NTH Tray Handler is an automated solution designed to make tray handling more efficient and reliable. It seamlessly fits into your existing production process, handling the loading and unloading of trays without interrupting your workflow. This system keeps parts moving smoothly, reduces manual oversight, and helps your production line run more efficiently.

Industrial companies are often frustrated that their assets are not running optimally. They suffer from excessive downtime and quality issues without the insight required to solve these problems. Automation NTH created the OEE Optimizer® tool to provide a simple way for industrial companies to generate insight into production issues. This insight can be turned into action on the production line, which results in optimized OEE, significant cost savings, and increased production.

The Heat Staking machine on the FLEXBASE platform provides manufacturers a proven, reliable heat stake process. Like other applications that are built on the FLEXBASE platform, it is highly configurable, scalable, and can be deployed quickly. A Heat Staking machine can be a stand-alone cell or part of a system connected to other FLEXBASE cells.

Download our comprehensive guide to learn more about how to create a successful automated manufacturing system for your organization.

©2026 Automationnth – All Rights Reserved | Privacy Policy