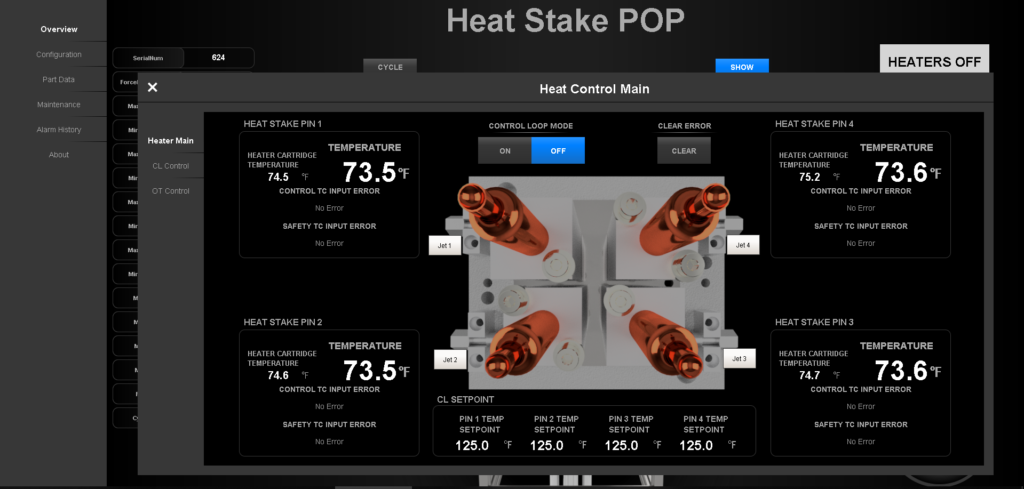

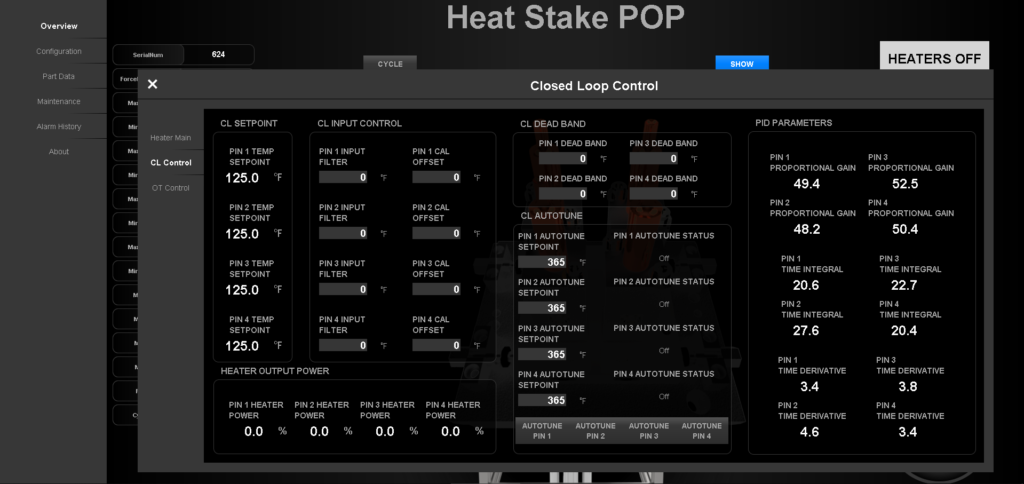

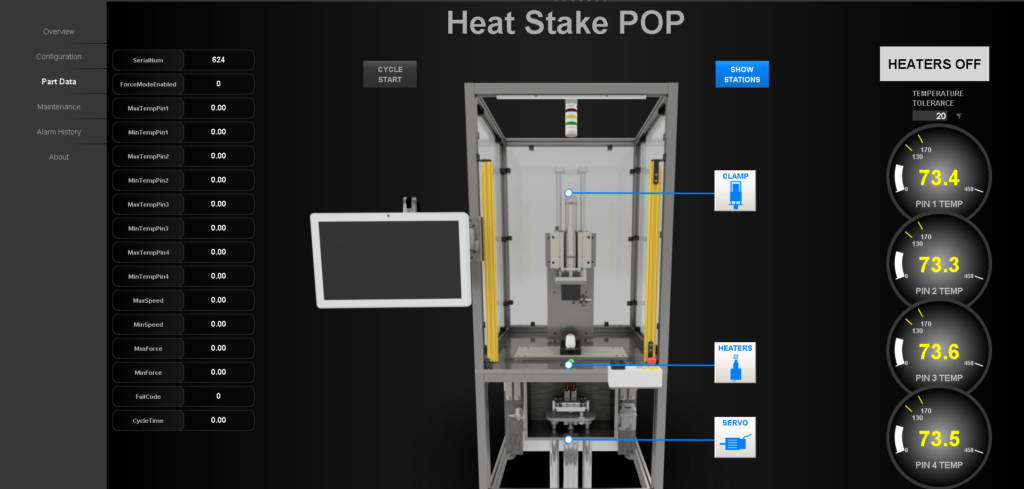

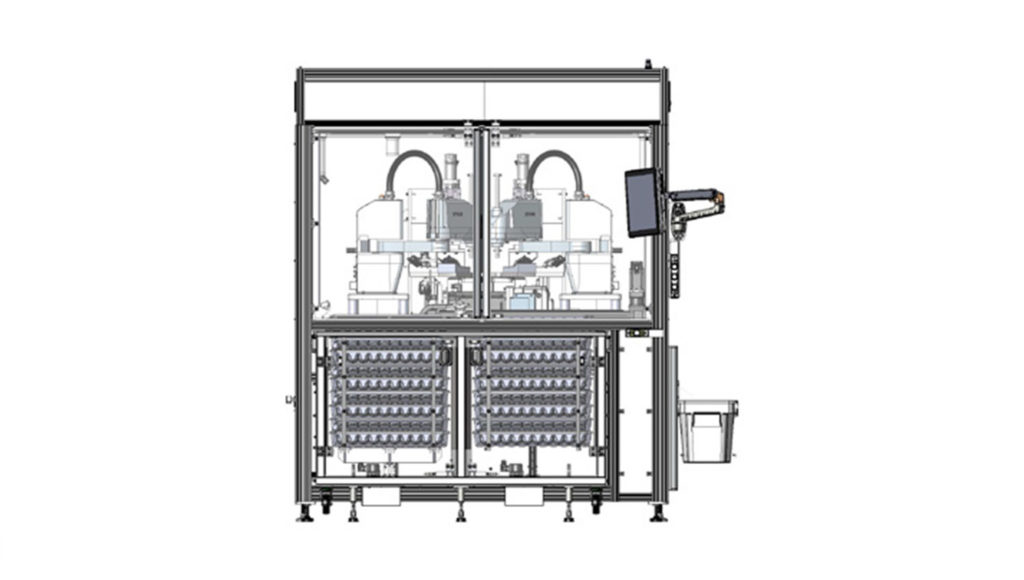

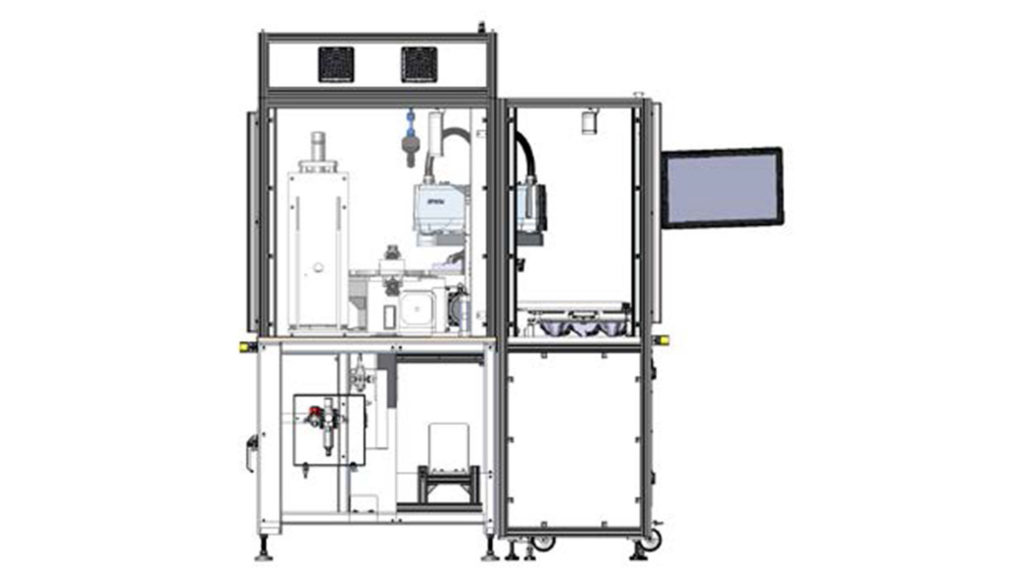

The Heat Stake machine on the FLEXBASE platform provides manufacturers a proven, reliable heat stake process. Like other applications that are built on the FLEXBASE platform, it is highly configurable, scalable, and can be deployed quickly. A Heat Staking machine can be a stand-alone cell or part of a system connected to other FLEXBASE cells.

Download our comprehensive guide to learn more about how to create a successful automated manufacturing system for your organization.

NASHVILLE

282 Mason Rd

LaVergne, TN 37086

615.793.7704

SAN DIEGO

13955 Stowe Dr.

Poway, CA 92064

619.780.7864

Fill out the form below to start a conversation.

©2023 Automationnth – All Rights Reserved | Privacy Policy