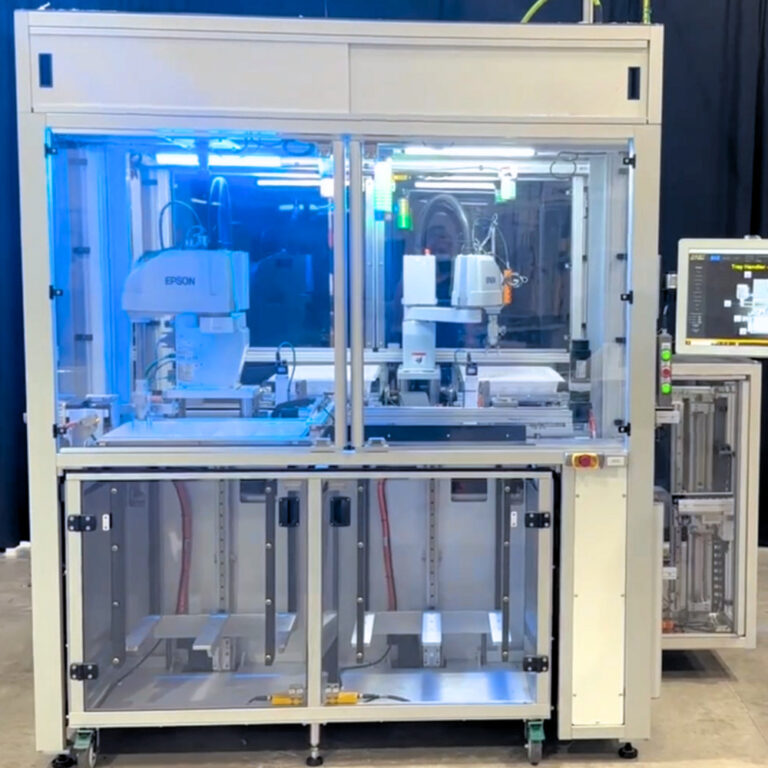

AUTOMATION NTH TRAY HANDLER

UNINTERRUPTED PRODUCTION with the Automation NTH Tray Handler

The Automation NTH Tray Handler is an automated solution designed to make tray handling more efficient and reliable. It seamlessly fits into your existing production process, handling the loading and unloading of trays without interrupting your workflow. This system keeps parts moving smoothly, reduces manual oversight, and helps your production line run more efficiently.

Tray Handler Benefits

EFFICIENCY

- Automation NTH Tray Handlers are engineered to ensure seamless product flow, maximizing operational efficiency and reducing the need for manual intervention.

OPTIMIZED THROUGHPUT

- Tray Handlers are designed to never be a bottleneck in achieving optimal Overall Equipment Effectiveness (OEE) or cause production stoppages.

Seamless Integration

- With a design that complements your existing processes, our Tray Handlers maintain your cycle time without over engineering.

Tray Handler FEATUREs

Continuous Operation

Effortlessly load and unload new trays without pausing your equipment, ensuring uninterrupted production.

Invisible to Operations

Tray exchange times are integrated seamlessly, making them virtually unnoticeable in your process.

Extended Autonomy

Our Tray Handlers significantly increase operator independence and walk-away time, reducing labor costs and errors.

Advanced Detection Systems

Crooked Tray Detection: Automatically identifies and handles tray misalignments.

Tray Orientation Detection: Ensures correct tray positioning every time.

Inbound Inspection: Verifies that the tray and product are located in the right place, enhancing quality control.

Integrated Part Tracking

Maintains a precise record of parts throughout the process.

Active Product Volume Monitoring:

Equipped with visual and audible alarms, ensuring operators are promptly alerted to volume discrepancies

HOW THE TRAY HANDLER WORKS

Smart Inspection

Incorporates inbound and outbound inspections with cameras at key points for precise verification.

Serialized Tray Tracking

Uses barcode stations for effective part data aggregation.

Precise Positioning

Features a registration sensor for accurate tray positioning during loading and unloading.

Operator Safety

Light curtains protect operators during tray exchanges, with a smart safety system that unlocks only when necessary.

Enhanced Ergonomics

Ergonomic pump carts and the option to integrate Automated Mobile Robots (AMRs) replace manual carts, reducing physical strain on operators.

The Guide to

Successful Automated Manufacturing

Download our comprehensive guide to learn more about how to create a successful automated manufacturing system for your organization.