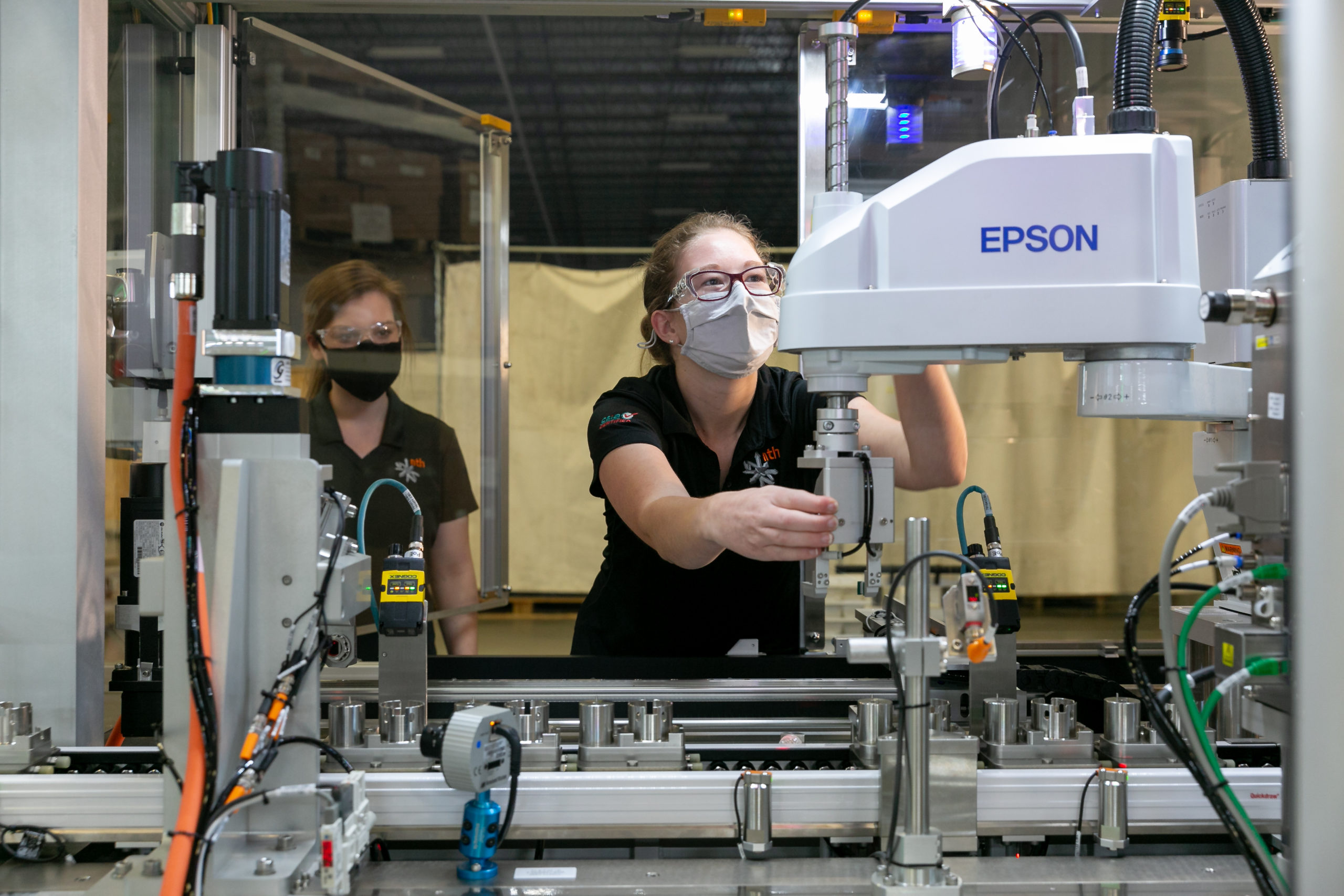

Step 1—When to Automate

This is Step 1 in an 11 part series that shares insights about how manufacturers can successfully implement custom automated systems.

This is Step 1 in an 11 part series that shares insights about how manufacturers can successfully implement custom automated systems.

Step 2 describes the role of an automation architect and the initial steps to take after hiring an automation architect.

Step 3 discusses how to create the right team to plan, implement, and operate automation. Learn about key roles and when to engage them.

Purchasing automation equipment is challenging. Step 4 describes how Automation NTH helps manufacturers reduce risk in supplier selection.

Step 5 discusses how a contract helps set expectations clearly up front and reduces potential conflict as the machine enters production.

Step 6 discusses how the team analyzes the design of the product, required quality and production levels, acceptance criteria, and other requirements.

Step 7 examines project execution and its typical project tasks, project management, and factors that are critical to success during debug.

Step 8 examines the process for a Factory Acceptance Test, including how the timing of the test plays a critical role in equipment success.

Step 9 discusses how to train operator and maintenance personnel to ensure they succeed with the automation equipment.

Step 10 reviews how the equipment is installed and started up at a manufacturer’s facility.

After the equipment enters production there will still be issues to resolve and opportunities for optimization. Common issues include unplanned downtime, low yield, and slow cycle time.

Download our comprehensive guide to learn more about how to create a successful automated manufacturing system for your organization.

NASHVILLE

282 Mason Rd

LaVergne, TN 37086

615.793.7704

SAN DIEGO

13955 Stowe Dr.

Poway, CA 92064

619.780.7864

Fill out the form below to start a conversation.

©2023 Automationnth – All Rights Reserved | Privacy Policy