In order to deliver custom automation equipment, Automationnth uses a unique business model by pairing our controls engineering and project management expertise with the mechanical capabilities of Certified Automation Partners (CAPs).

We frequently get asked how Automationnth‘s business model can possibly be cost competitive with vertically integrated machine builders. Their perception is that we are a “middleman” when we build machines due to our use of mechanical partners. This is a logical question, so we want to shed light on how we make this model work economically for our customers.

Superior Total Cost of Ownership

Manufacturers should optimize their automation equipment’s Total Cost of Ownership per unit of output. Total Cost of Ownership includes the initial price of the automation equipment, but also the support personnel, scrap, repairs, and training. The equipment’s output is driven by its OEE and how quickly it enters production.

Through its leadership in control system integration, Automationnth delivers best-in-class controls that results in equipment with superior speed to production, OEE performance, requirements adherence, and usability. Our OEE Optimizer® analytics tool and on-site support ensure that manufacturers get more output from their equipment. Our training services help a manufacturer’s support organization get up to speed quickly on key concepts.

This model results in a superior Total Cost of Ownership and equipment output.

More Than Just a Middleman

Calling Automationnth a middleman implies that we are just a broker between the end user and the CAP. However, our involvement with the CAP goes far beyond the initial procurement of services. We are deeply embedded with our CAP throughout the mechanical design and build process, influencing decisions along the way to optimize the machine’s functionality.

Our controls engineers work on the CAP’s plant floor throughout the machine’s debug process. We work hand-in-hand with the CAP to quickly identify and resolve issues until the machine is in production.

Our partnership with CAPs enables us to be a connective thread for our customers and provide consistent controls leadership across geography, scale, capability, and technology.

Automation Cost Elements

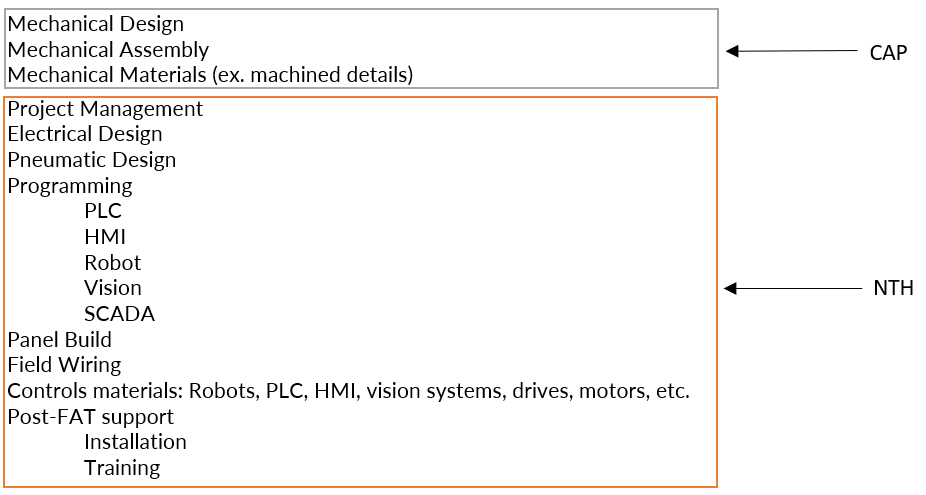

Our automation equipment consists of the following cost elements:

The mechanical elements provided by the CAP typically represents only ~30-40% of the total automation project cost. Automationnth’s controls hardware and labor expenses have more impact on the cost structure of a project than the CAP.

We optimize overall cost structure and capability for each project through our choice of CAP

Vertically integrated machine builders vary greatly in size and their overhead burden typically is in lockstep with their size: a large machine builder has more overhead burden than a small one.

The CAP model enables us to match our partner with the scale of the program and optimize the cost structure for that specific project. We use CAPs with lower cost and overhead for smaller projects, and larger CAPs for projects requiring more scale. For large programs, we can use both big and small CAPs and create a better weighted average overhead cost structure than a one-size-fits-all vertically integrated machine builder.

Minimal Risk “Pad” in Quotes

The price tag of automation equipment can quickly get inflated if machine builders perceive risks in the scope of the project. This extra “pad” in price helps ensure that the machine builder doesn’t get burned from these risks on a fixed price project.

As experts in controls engineering, Automationnth has a lot of confidence in the numbers we quote related to controls design, programming, and materials. We take great efforts to reduce risk by clearly defining requirements and understanding the customer’s process. Machine builders with less capable controls engineering and more variable results will need more risk pad in their quotes.

CAPs also do not need pad in their mechanical quotes. As experts in automation systems, we ensure our CAPs have a robust scope of work and minimize their risk, which means they can take pad out of their quotes to us.

Purchasing Power

Automationnth consistently maintains the procurement of controls-related materials such as robots, PLCs, vision systems, and HMIs. This provides us with purchasing power and cost advantages that we are able to pass on to our customer.

Ultimately, manufacturers can assess our cost competitiveness for themselves by getting a quote from us and seeing how our equipment performs. We invite manufacturers to put us to the test and work with us for their next automation program.