All custom automation projects carry some amount risk. Unexpected issues inevitably emerge over the course of a project and increase with the complexity of an application. An automation company that uses a rigorous methodology to assess and manage risk will have a much higher probability of maintaining schedule and budget despite the many challenges along the way.

At Automationnth, five factors are especially important to help us reduce risk throughout a project: understanding requirements, prototyping, project management, our culture, and our resources.

Understand Requirements

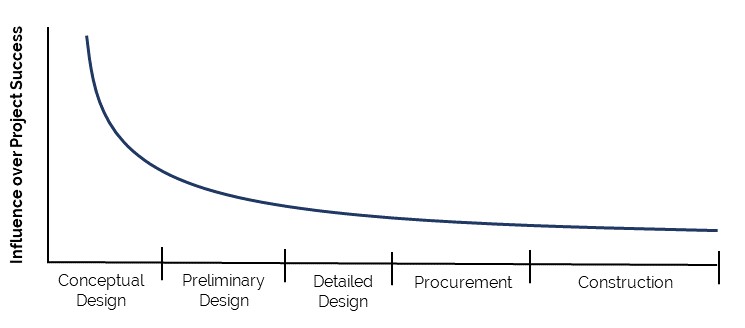

- Upfront Engagement in Defining Scoping and Requirements: We believe that the early phases of a project are the most impactful. For that reason, we partner with our customers to help them define scope and requirements and minimize project execution risk.

- Process Understanding: Understanding our customer’s production processes and requirements is critical to manage risk in automation projects. Our approach ensures that we will understand the customer’s processes and requirements at least as well as the they do, if not better.

Prototyping

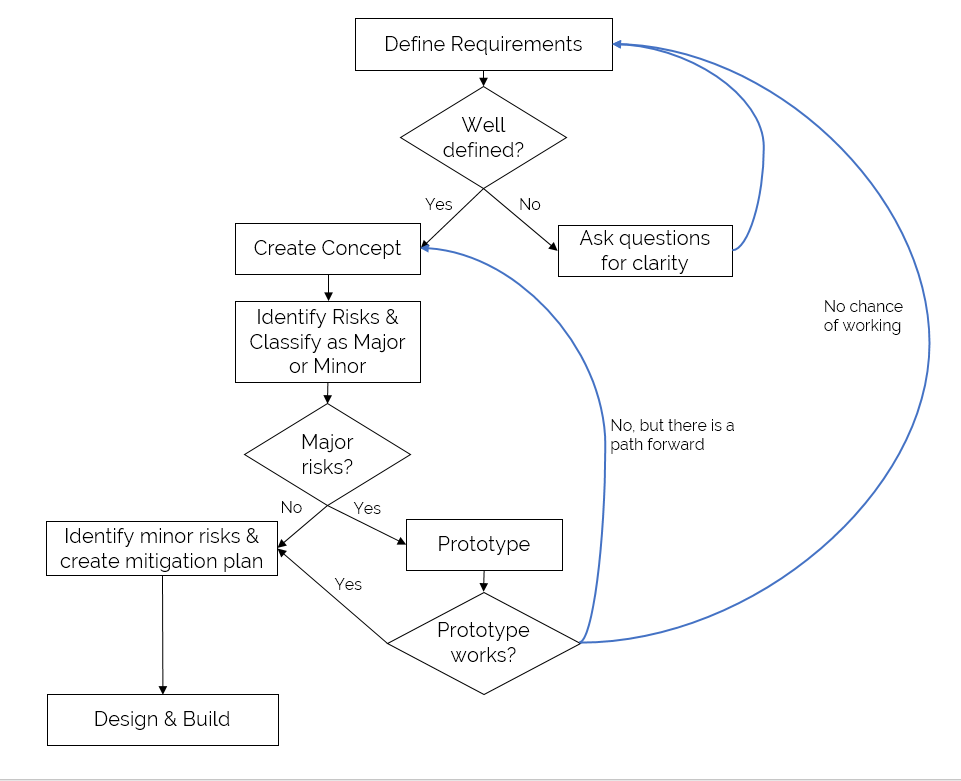

- Prototyping: When an automation concept has major risks, we prefer to create a prototype to mitigate those risks before moving to full scale production automation. The flowchart in Figure 1.1 shows our decision-making process to determine when a prototype is appropriate.

- Simulation: We utilize sophisticated software to simulate automation systems. This reduces risks of cost and schedule overruns by allowing us to optimize motion efficiency and uncover mechanical issues prior to fabrication. We also simulate workflow on the plant floor to help us understand required staffing levels for a system. Learn more about a case study that uses simulation to improve product delivery here.

Project Management

- Procedures: We achieved CSIA Certification through an external audit of our processes and procedures. Our documented processes, Continuous Improvement Program, and project audits ensure that quality is consistent, and risk is minimized.

- Schedules: Our Project Managers utilize Microsoft Project software to create and manage project schedules.

Philosophy/Culture

- We Believe That Simple is Better: Simple automation solutions require more thoughtful engineering but reduces risk.

- Our Employees Have A “Game On” Mentality: Setbacks are inevitable when we try to solve tough problems. When this happens, we can either let the wind out of our sail or say, “Game On!” We hire people who share this mentality and actively promote it as part of our culture. This mentality helps us overcome challenges that might stop other automation companies.

Resources

- Engineers Trained Through NTH University: Engineers joining Automationnth earn a “Masters in Automation” by completing courses in a comprehensive controls and automation training program we developed called NTH University. This robust training program ensures our engineers are highly competent with a consistent approach to automation projects. View more information about NTH University.

- Templates: Our engineering team uses standard programming templates for rapid development and consistency of quality.

- Certified Automation Partners: Our Certified Automation Partners have passed a rigorous assessment to evaluate their adherence to automation best practices. CAPs also provide valuable expertise and additional insight into automation challenges. View more information on Certified Automation Partners.