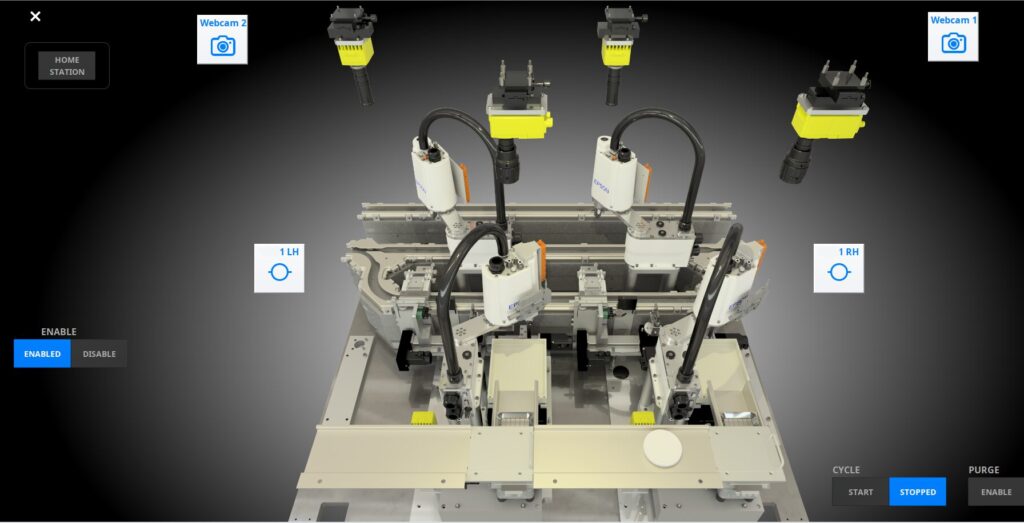

Station Control, a vital component of our industrial automation solutions, enables operators to isolate a single sub-assembly or station. The ‘Station’ definition varies across applications, but typically includes hardware chosen to perform a specific task controlled by a dedicated set of instructions in the PLC. These stations are integral to our robust suite of manufacturing automation equipment and custom manufacturing solutions. Common examples of components that would make up a station include:

- Robotic Manufacturing Solutions: A robot which picks parts off a conveyor and places them in a tray (‘Pick & Place’ Station)

- Automated Inspection Systems: A camera which looks for defects or provides coordinate targets for a robot (‘Vision Inspection’ Station)

- Precision Automation in Manufacturing: A liquid handling unit which fills a container to a precise volume (‘Dispense’ Station)

A conveyance system which transports components throughout a cell would not be considered a Station. The ability to isolate a station and control it independently of a larger system is useful for optimizing process performance, debug, and general maintenance. This feature seamlessly integrates with our comprehensive suite of manufacturing automation solutions.

The ability to isolate and control these stations independently offers significant advantages in optimizing process performance, debugging, and general maintenance. This feature seamlessly integrates with our comprehensive suite of manufacturing automation solutions.

Experience the power of seamless integration and precise control with our Station Control feature, designed to enhance manufacturing efficiency and productivity across a range of industrial applications.