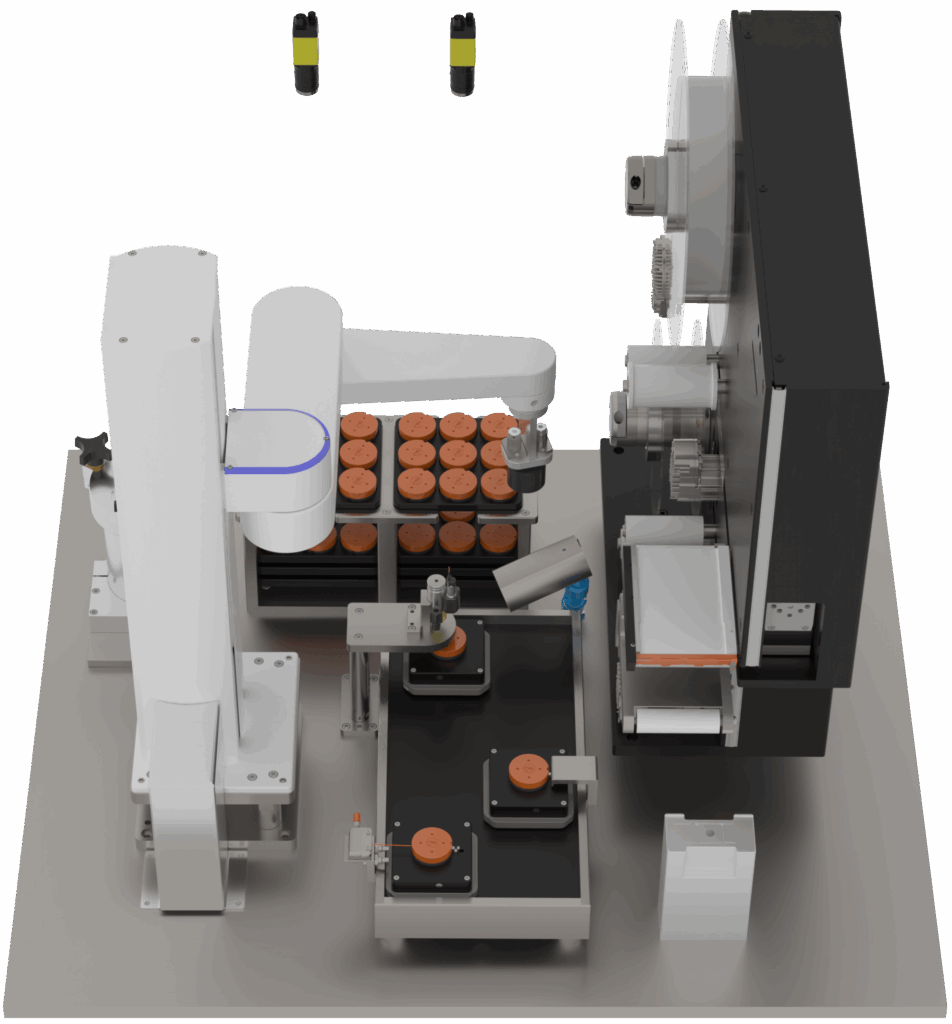

Automation NTH is proud to introduce our latest trade show machine: Diagnostic Test Assembly Cell (DTAC). Designed to showcase our expertise in delivering compact, efficient, and cutting-edge automation solutions, DTAC represents the pinnacle of automation technology for the Life Sciences and Medical Diagnostics industries.

DTAC combines advanced technologies, modular design, and unparalleled precision to create a captivating demo that demonstrates the full assembly process of a consumable diagnostic device. From reagent application to part verification, this machine highlights the seamless integration of critical automation processes.

Key Technologies Powering the DTAC

At the heart of DTAC are industry-leading automation tools and technologies, including:

- NTH Reel Feeder: Precise web handling for reel-fed assembly and labeling applications.

- NTH Tray Handler: Efficient part feeding and handling.

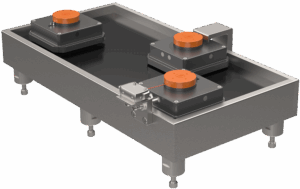

- NTH FLEXBASE Platform: A modular foundation for rapid customization and development.

- Planar Motion Platform with 6‑Degrees of Freedom: For asynchronous and highly flexible part handling.

- Precision Dispense Technology: Accurate reagent application for diagnostic tests.

- Collaborative Robot: Safe, human-friendly automation without the need for hard guarding.

- Inspection Systems: Advanced AI-enabled cameras ensure part identification, label inspection, and product verification.

DTAC in Action

The assembly process demonstrated by DTAC is a streamlined, fully automated workflow for creating diagnostic test consumables.

- Reagent Application: The process begins with a disc (the capture device) receiving reagents tailored to the specific diagnostic test.

- Sealing: The disc is sealed with a protective capping layer.

- Inspections: Multiple inspections ensure quality, accuracy, and compliance throughout the process, leveraging Cognex vision systems for part verification and AI-driven label inspection.

Designed for Life Science Automation

Built on the versatile NTH FLEXBASE platform, DTAC offers unmatched flexibility for high mix, low volume production. This modular design enables rapid customization and reduced time-to-market for tailored automation systems.

Key attributes of DTAC include:

- Compact Design: Saves valuable space in cleanrooms.

- No Guarding Required: Designed with collaborative robotics and safety in mind, eliminating the need for hard guarding or light curtains.

- Recipe-Driven Formats: Easily adapts to different production requirements, supporting high mix, low volume manufacturing.

A Game-Changing Trade Show Experience

Automation NTH’s goal with DTAC was to create a dynamic, interactive demo machine that would capture attention while demonstrating the cutting-edge automation capabilities and solutions we provide our clients. By integrating collaborative robotics and planar motor technology, we’ve delivered a machine that is not only highly functional but also visually captivating and safe to interact with.

DTAC is a testament to Automation NTH’s commitment to advancing life science and medical diagnostic automation by delivering solutions that improve efficiency, precision, and operator autonomy.

Experience DTAC

Visit Automation NTH at our next trade show to experience DTAC in action. See firsthand how we’re revolutionizing automation for the Life Sciences industry with innovative solutions designed to meet the unique challenges of high mix, low volume production.

Upcoming Tradeshows

MD&M West: February 4-6, 2025 Anaheim, CA Booth 4515

Interphex: April 30-May 1, 2025 Javits Center, NYC Booth 3061

MD&M East: May 20-22, 2025 Javits Center NYC 1613

Schedule your demo today

Automation NTH

We Turn Automation into Your Competitive Advantage!

Increase Production Capacity

Improve Product Quality

Enable Operator Autonomy