THE SITUATION:

A global leader in eye care device manufacturing approached Automation NTH to help provide a solution to its “information overload” on the manufacturing floor. As this customer grew, their manufacturing equipment multiplied, along with new processes and mountains of data coming from the manufacturing floor. The environment became cumbersome and a bit complicated to manage. There was a separate platform to track data for each piece of automation equipment, along with additional supervisory systems to track information across production lines and the entire site. These systems used a combination of paper and electronic records, often with duplicate and conflicting information between them.

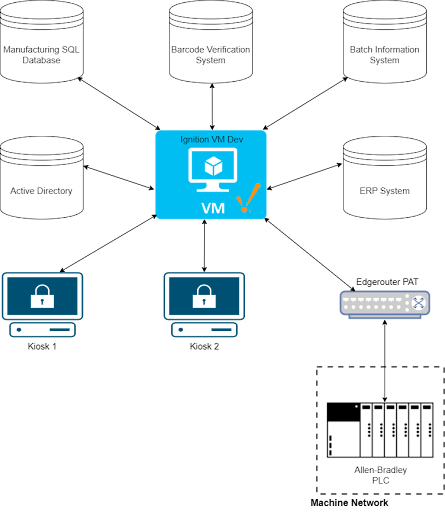

There was a need to simplify the data for each production line, and each site. Automation NTH was brought in to implement a single, seamless solution, aggregating multiple unconnected platforms into a single SCADA solution.

MULTIPLE PLATFORMS

THE SOLUTION:

With many years of SCADA experience across a range of custom automation implementations, Automation NTH implemented SCADA as a hub for all the existing data systems. The SCADA system is modular and scalable across all manufacturing sites.

A singular screen can show multiple machines across multiple sites. Overall Equipment Effectiveness (OEE) can be monitored from anywhere on the site network across multiple machines. Operators can view data at a macro level, such as OEE as shown on the left. Or, operators can view at a micro level, such as the Time Series Part Data shown below.

The end result was a complete demonstration of Automation NTH’s ability to unify this customer’s manufacturing processes while eliminating several manual, redundant, and time-consuming tasks.

Automation NTH provides customers with world-class automated manufacturing systems and solutions. Its services include automation consulting, custom automation systems, and automation optimization.

FUTURE OPPORTUNITIES

Automation NTH is implementing this SCADA for this particular customer on five (5) different pieces of equipment in countries across the world. SCADA aggregates and simplifies the retrieval of data from all locations and significantly increases efficiency and throughput for their manufacturing.

WHAT IS SCADA?

SCADA systems provide real-time monitoring and control of critical manufacturing processes, ensuring precision and consistency in the production of medical devices, among other numerous advantages to a medical device manufacturing company. This technology allows for centralized oversight of various interconnected systems, such as equipment calibration, temperature control, quality assurance, and inventory management.

With SCADA, manufacturers can detect anomalies or deviations in the production process instantly, enabling swift corrective actions and minimizing the risk of defects or recalls. Moreover, SCADA systems improve operational efficiency by automating routine tasks, reducing human errors, and optimizing resource utilization. Overall, by enhancing quality control, traceability, and operational efficiency, a SCADA system can significantly improve the reliability, safety, and compliance of a medical device manufacturing company’s processes, ultimately benefiting both the company and the patients who rely on its products.

ABOUT AUTOMATION NTH

Automation NTH provides world-class automated manufacturing systems and solutions. Providing our customers with Automation Consulting, Custom Automation Equipment, and Automation Equipment Optimization.