Automation Architects

An industry leading Life Science company had been trying to automate a key element of its product assembly for 7 years without success. Their product, a Class II medical device, requires a process to insert a component with the thickness of two hairs into a hollow member that is not much larger. Currently workers must insert the component by hand with the assistance of magnifying lenses. As a result, production efforts have been constrained by this slow and tedious process which causes operator fatigue and creates potential for damaged product. Multiple companies attempted to provide an automation solution without success.

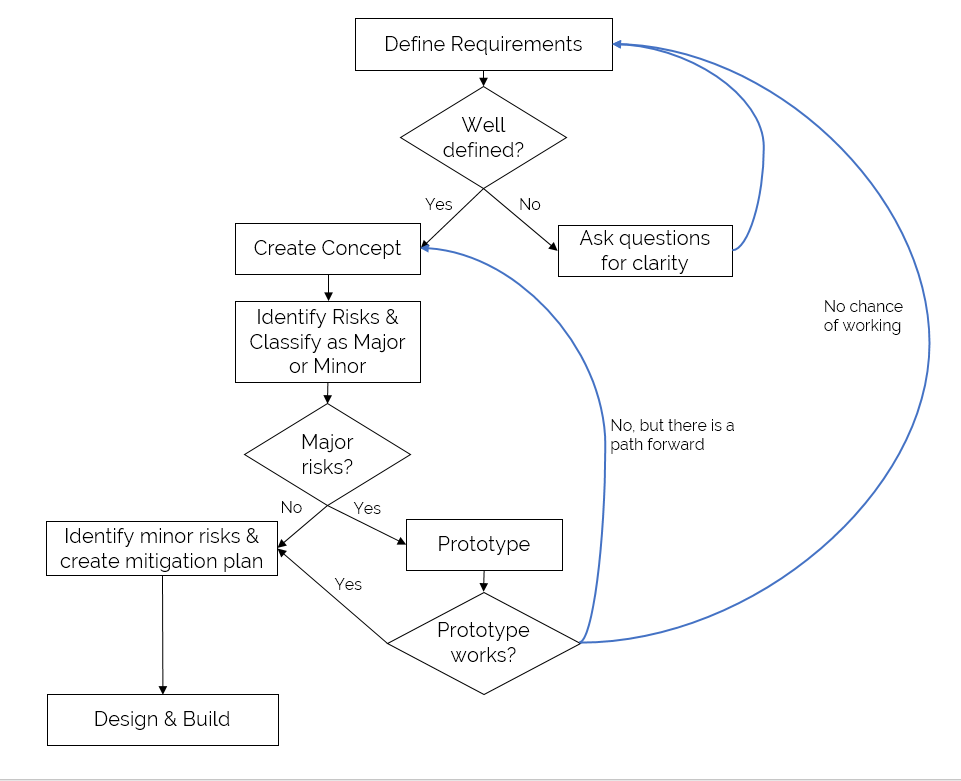

Automationnth approached this problem by assessing a proof of concept system developed by another automation company. We conducted a risk and gap analysis of the system to help the customer understand if the proof of concept could be adapted into a high-volume production system.

These analyses highlighted a significant risk in the concept. The fragile component could be damaged in the assembly process, turning the whole product into a failed part. It also showed that the concept did not have the capability to fully assemble the components. However, we determined that these challenges were surmountable, and we outlined a clear path towards automated assembly.

In an effort to mitigate the risk we recommended that they first develop a prototype system that provided solutions for the identified risks and gaps before proceeding to full production automation.

Requirements Gathering

Understanding the customer’s production processes and requirements is a critical step to reduce risk in automation projects. The approach taken by Automationnth ensures that we will understand the customer’s processes and requirements at least as well as the customer does, if not better.

In this case, the operators showed us how they were completing their manual processes and we observed their work cycles. We then interviewed them to understand the typical failures and challenges in the assembly process. We conducted time studies and interviews with management to understand all aspects of the production system.

Rapid Protyping

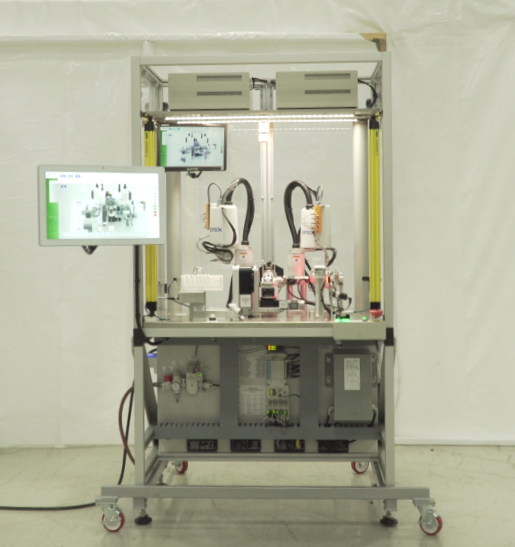

We started the prototype design with a desire to reapply as much as possible from the proof of concept, including hardware and design, to save the customer time and expense.

To create the first prototype design, we calculated the necessary physical layout of the system so that the robots could reach all areas with as small of a footprint as possible. We then engaged our mechanical partner to create a 3D concept for the system. In parallel, we used advanced software to simulate the robotic movements in the assembly cycle, creating a “digital twin” of the prototype. Our digital modelling efforts ensured that the robots could reach all their points efficiently before we committed to any metal fabrication. The digital twin also helped us learn that we needed to move robots and stations in the physical layout to optimize motion efficiency. Our thorough pre-fabrication modelling ultimately saved the customer time and money with less rework.

Video of prototype simulation

After simulations confirmed that our physical layout was feasible, we authorized our mechanical partner to start building the prototype.

Debug & Optimization

Throughout the mechanical build, our controls engineers continued improving the robot, PLC, and vision programming in order to achieve the highest possible OEE for our customer. We used this valuable period to improve fault recovery time, increase reliability, and optimize robot and pneumatic motions to overlap when possible. We also organized the PLC, robot, and vision code to optimize cycle time.

Automationnth also proactively found a way to increase yield of the product. Previously, when one of the components was slightly off-spec (which was not uncommon), it would have to be rejected, causing scrap and lost production time. We devised a mechanical solution that allowed the robots to handle these components even if they were off-spec. We also identified another component with tolerance issues which were not visible to the naked eye and therefore had not previously been identified. As a result, the customer was able to visit the supplier of the component to resolve the issue before the start of high volume production.

This work resulted in a 63% cycle time reduction from the prototype’s first production cycle.

We integrated data generated from the prototype with the data available in our customer’s corporate database, which assisted our customer in meeting a requirement to maintain traceability of all the product components and process parameters. Pulling data directly from the corporate database enabled us to use their active directory for user authentication and obtain incoming product component signature data. Armed with this data, the system knew component test results and the robots would skip bad components automatically.

First System Results

After our customer struggled for 7 years to find a successful automation solution, Automationnth successfully passed the factory acceptance test on the prototype system only four months after receiving the customer’s Purchase Order. The customer provided feedback that after their testing, “the assembly resulted in the cleanest data ever generated in this application.”

The prototype system’s OEE consistently hovered near 100.

Transition to Full Production System

After accepting the successful prototype and validating that risks had been mitigated, the customer was ready to move to a full production system. Once again, Automationnth created a digital twin to rapidly prototype, improve the physical layout to ensure that robots could reach every position, and optimize the process. The digital twin helped us develop a better design and reduce time spent debugging the system by a few months, saving the customer large amounts of money and time.

The full production system added scope to provide visibility to key Statistical Process Control (SPC) values on the HMI and how they’re trending over time. Operators and management are also capable of viewing key production data on their mobile devices.

High Volume Production

After a successful Site Acceptance Test of the first production system, the customer wanted Automationnth to pursue a high volume system. As before, Automationnth created a concept then developed a digital twin to rapidly prototype and optimize it.

The high volume system requires little operator involvement. The operator only has to deliver additional trays to the systems every 7.5 minutes, allowing “lights out” automation.

To better understand how the automation would be integrated into the manufacturing environment, Automationnth utilized FlexSim software to create a simulated factory environment. Our simulation helped the team understand how operators would be able to run the system and how efficient they would be. It also confirmed the staffing levels required with lifelike, random circumstances.

Summary

This project illustrated the unique strengths of Automationnth , including:

- Creating an automation concept that exceeds the customer’s expectations

- Managing risk through our rigorous methodology

- Customer collaboration to deeply understand requirements

- Compressing project schedules through rapid prototyping and use of digital twins

- Managing mechanical partners on a complex turnkey project

- High precision assembly of medical devices

- Production data integration into customer databases

Strategic partnership with the customer was incredibly important for the project’s success. The customer engaged us upstream in the automation development process, which enabled us to greatly decrease the project’s risk. The trust built between the two companies also enabled a free flow of ideas and collective problem solving and led to a project that was on schedule and within budget.