HMI Screen Design Principles

Human-Machine Interface (HMI) screens play a pivotal role in industrial automation equipment, serving as the primary touchpoint for operators to interact with their machinery. An effective HMI can streamline operations, improve efficiency, and reduce errors.

Automation NTH is committed to excellence in HMI screen design. We integrate the following key elements into our equipment to ensure optimal performance and user experience:

- User-Centered Design: An HMI should be designed keeping the operator’s needs and tasks in mind. This requires understanding the job, the environment, and the challenges the operator faces. The layout, controls, and visual cues should be intuitive and mimic the operator’s thought process.

- Clear and Consistent Visualization: Information should be presented in a manner that is easy to digest.

- Real-time Data Visualization: A well-designed HMI screen will display process parameters, status, and part quality metrics in real-time. This enables operators to identify deviations or anomalies instantly, allowing for quicker interventions.

- Historical Data Access: While real-time data helps with immediate issues, historical data helps identify patterns or recurring issues. Access to data over hours, days, or weeks can allow operators to identify trends in the process, which might not be evident from a single snapshot.

- Prioritization of Information: Not all information is of equal importance. Alarms and critical data should be prominently displayed and differentiated from less crucial information. This ensures operators can quickly address pressing issues.

- Adaptability: The best HMI designs can be adapted to different users, shifts, and types of equipment.

Automation NTH Approach To HMI Design

To illustrate how we use these principles in practice on our equipment, we will share Automation NTH’s approach to HMI design. To organize the screens we use a consistent display hierarchy:

- Level 1: Overview

- Level 2: Station Control

- Level 3: Sub-Station Control

- Level 4: Component Control

- Level 5: Component Support & Diagnostics

Level 1: Overview

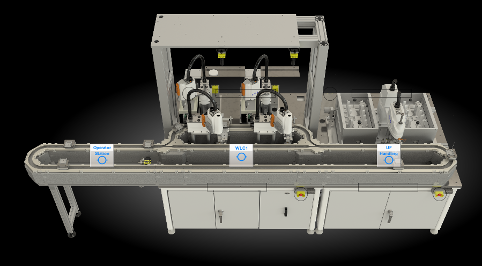

In the first level of the hierarchy, we display a photorealistic rendering of the overall machine with easily identifiable buttons for navigating to additional screens.

Level 2: Station Control

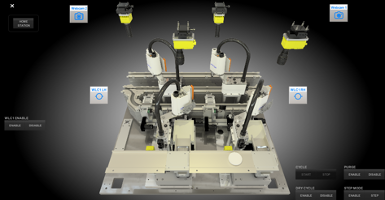

At Level 2 in the hierarchy, we display station level control including enabling, disabling, homing, starting stopping, purging, dry cycling, and stepping through sequences.

Level 3: Sub-Station Control

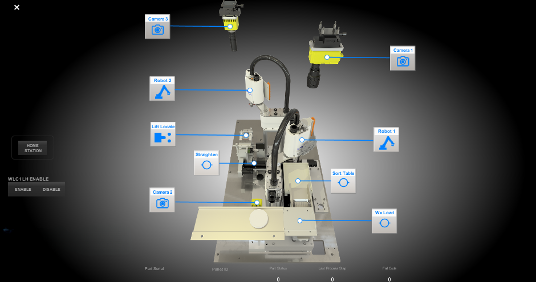

At Level 3 in the hierarchy, sub-station control allows for independent cycling of multi-up stations as well as access to sub-station specific components.

Level 4: Component

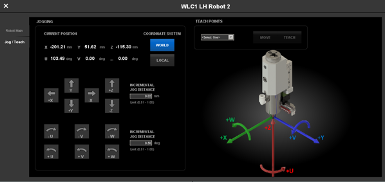

At Level 4 in the hierarchy, component control allows manual manipulation of component level items (robots, cameras, actuators, etc.). In this example, robot subroutine execution is accessible at the component level.

Level 5: Component Support & Diagnostics

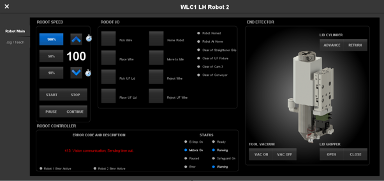

At Level 5 in the hierarchy, detailed support and diagnostics are accessible at the lowest UI level. The screen below allows for fine control over the robot end effector.

Summary

A great HMI screen is more than just a display. By prioritizing user needs, data, clear visuals, and adaptability, Automation NTH designs and deploys HMIs that enhance efficiency, safety, and productivity on our equipment.