A global Life Science manufacturer needed a turnkey automation solution for filling, weighing, capping, labeling, and palletizing tubes filled with a chemical reagent. The product line contained more than 900 permutations of tube, cap, and label combinations to be manufactured on this automated system.

In addition, the custom automation equipment required 100% inspection of Critical to Quality Attributes (CQA) and full traceability of process metrics across the entire product line.

This was a unique project because the customer hired a different System Integrator for the full program but they struggled with project management, controls, and getting the $1M+ line to commissioning and FAT. After learning about our experience in controls engineering, the medical device manufacturer called Automation NTH to see if we could take over the project and complete the system through SAT.

Requirements Analysis

Taking over on a project that was designed by another automation firm can be risky. In order to fully understand the state of the system, the requirements it needs to meet, and what engineering and project management activities need to be executed to complete the system, a thorough evaluation had to occur.

Our first step was to assess the customer’s requirements, evaluate the design of the existing equipment, and identify any gaps that needed to be addressed. Several areas of improvement were identified, and some stations needed to be completely redesigned. In order to get this equipment back on track and into production, we performed a systematic analysis of every station.

The function and design of each section of the equipment were tied to a User Requirement Specification (URS) line item, and we captured gaps in the URS to bring to the customer’s attention.

Addressing Gaps

There were also lots of environmental factors around the Scale Station that were currently making it difficult to separate “signal” from “noise.” The Scale Station was surrounded by a 36” diameter rotating dial, several 6-axis robots, and several Feeder Stations for feeding consumables (tubes and caps) onto the dial. A new scale nest was designed to mitigate excessive vibration from surrounding stations.

The Capping Station was another area that needed re-design. Cap torque was a Critical to Quality (CTQ) metric, and the existing actuator was insufficient. It used an out-of-date communications protocol, was difficult to perform maintenance on, and contained no closed-loop control for the precision required by the customer.

Automation NTH performed a cost analysis which proved that the additional cost of a more modern actuator would pay for itself in terms of savings in development time and maintenance. The new actuator contained integrated closed-loop Scale Nest torque feedback, as well as modern safety protocols, and allowed users to define custom parameters directly from the Human Machine Interface (HMI).

Added Value

Being Customer Centric is a core value at Automation NTH. We understood the difficult situation the customer was in. They invested significant time and money into a design, only to part with the original designer, and were in danger of a failed automation project. Automation NTH sought opportunities for the customer to leverage existing resources and minimize additional expenses.

One area of opportunity was at the Capping Station. As mentioned, capping torque is a CTQ metric, and the customer wanted to guarantee caps were placed properly onto tubes. The original design called for a camera inspection at the Dispense Station that was no longer necessary.

With the customer’s help, Automation NTH was able to repurpose the cameras at the dispense station to be used to visually confirm cap alignment at the capping station. This was a challenge because there were hundreds of combinations of tubes and caps that needed to be inspected, each with its own alignment criteria.

Ultimately, the effort paid off. The cameras were able to be integrated into the Capping Station and provided another layer of confirmation to the customer that each tube had a properly seated cap. The only additional hardware cost was for camera brackets.

Enhanced Opportunities

The ability to clearly see what the customer was dissatisfied with from previous automation experiences served as a silver lining. Automation NTH was able to use the information of past systems to create highly customized solutions that met customer needs.

Pipetting System

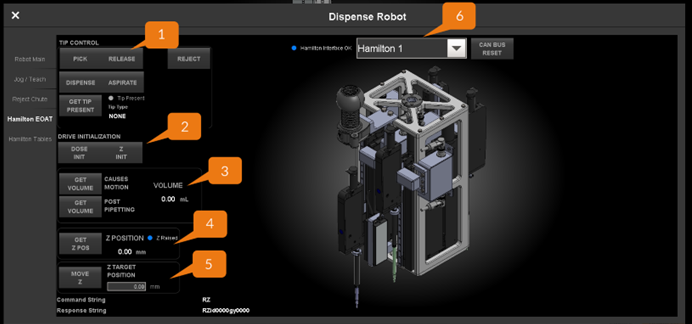

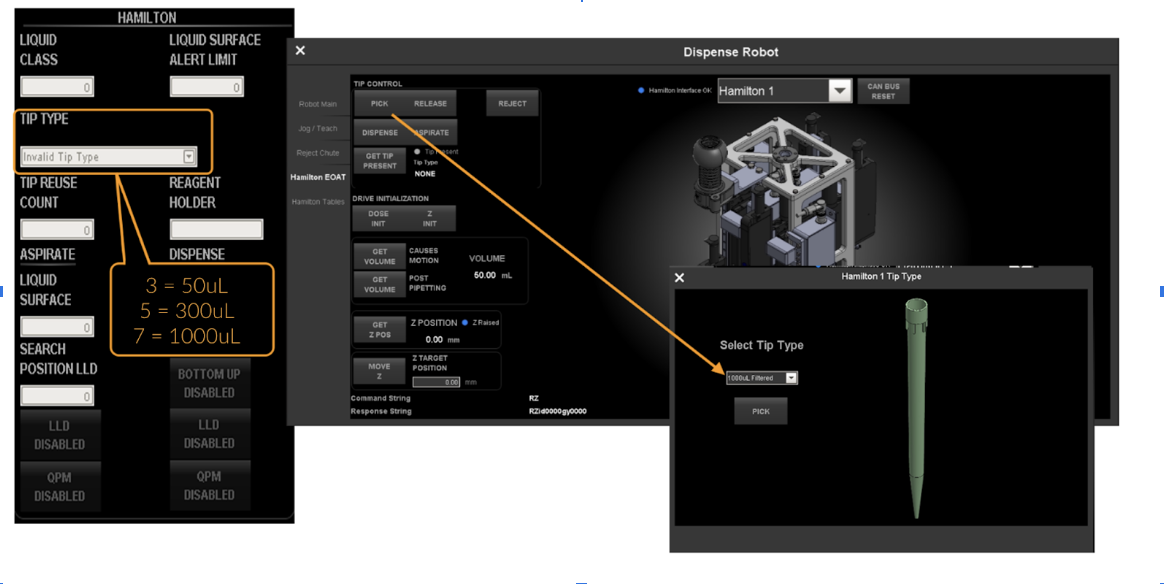

One area of enhancement was at the Dispensing Station. The customer had another machine with a similar pipetting system with an interface that they felt had deficiencies. The User Interface (UI) was not easily navigated, and was difficult to troubleshoot.

There were no diagnostic tools for when the system would fail, and maintenance was cumbersome. As a solution, Automation NTH completely rebuilt the UI which allowed for user-defined, highly customizable dispensing parameters. The parameters were all stored on the HMI and could be exported, edited offline, and re-imported for ultimate flexibility.

All communications to and from the pipetting system were kept in a log for troubleshooting, and the UI contained a real-time display of the active messages that the pipetting system was receiving.

|

Reference Number |

Description |

Details |

|

1 |

Control Pushbuttons |

Press to upload or download Hamilton data. |

|

2 |

Table Menu |

List of displayable Hamilton data. Press to display a different data set. |

|

3 |

Hamilton Select Drop Down Menu |

Use menu to select Hamilton. |

|

4 |

Table Display |

Displays the table selected from the Table Menu |

|

5 |

File Name Field |

Displays a field to enter the file name. |

|

6 |

Export/Import Table Pushbuttons |

Press to export current table or import a new table. |

|

7 |

Batch Processing Window Navigating Button |

Navigates to the Hamilton Table Batch Processing screen. |

Dispense Robot

Liquid Class Offline Editing

Dispense Robot – Tip Type – HMI Screen

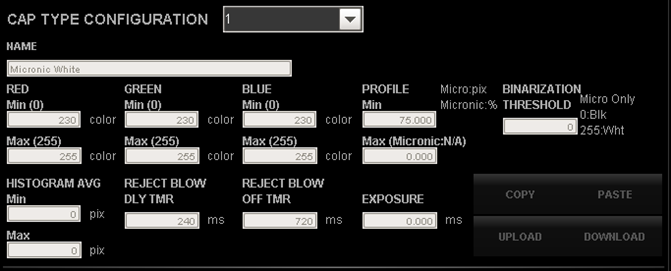

Vision System

Another area of improvement was an Inspection Station which inspected and sorted caps of various sizes and shapes. The original camera did not allow the customer to define size, shape, and RGB limits from the HMI. The camera was replaced with a Cognex InSight model which allowed for custom parameterization:

Cap Type Configuration Tab

This allowed the customer to fine tune their inspection, which was necessary for the wide range of parts they were running.

Results

Overall, the customer received a piece of equipment that met all the original requirements and exceeded expectations regarding the high level of parameterization capability. The customer was very impressed with the ability for Automation NTH to take an unfamiliar piece of equipment, assess customer needs, implement the necessary changes, and deliver a fully working piece of automation.

About Automation NTH

Automation NTH provides customers with world-class automated manufacturing systems and solutions. Its services include automation consulting, custom automation systems, and automation optimization.

If you have a current system that is not meeting the required performance and you’re interested in system optimization, contact us.