AI Vision Inspection Process Overview

AI-driven vision inspection systems are reshaping quality control in modern…

AI-driven vision inspection systems are reshaping quality control in modern…

https://www.automationnth.com/wp-content/uploads/2025/11/drug-delivery-device-autoinjector.mp4

https://www.automationnth.com/wp-content/uploads/2025/11/drug-delivery-device-dispense-and-cure-application-video.mp4

Vision-Triggered Adhesive Jetting Cell Demonstrates Geometric Control and Robust Bonding…

Automated Glue Dispense and Cure System Enhances Wearable Medical Device…

A leading Medical Device manufacturer approached Automation NTH with the…

Hamilton Medical Inc., a global leader in ventilator and respiratory…

A leading pharmaceutical manufacturer approached Automation NTH with the need…

Beyond Our Walls: How Automation NTH Customers Can Drive Success…

Automation NTH tackled a medical device manufacturer’s challenge of scaling…

Automation NTH has integrated a magnetic-levitation (maglev) system, XPlanar from…

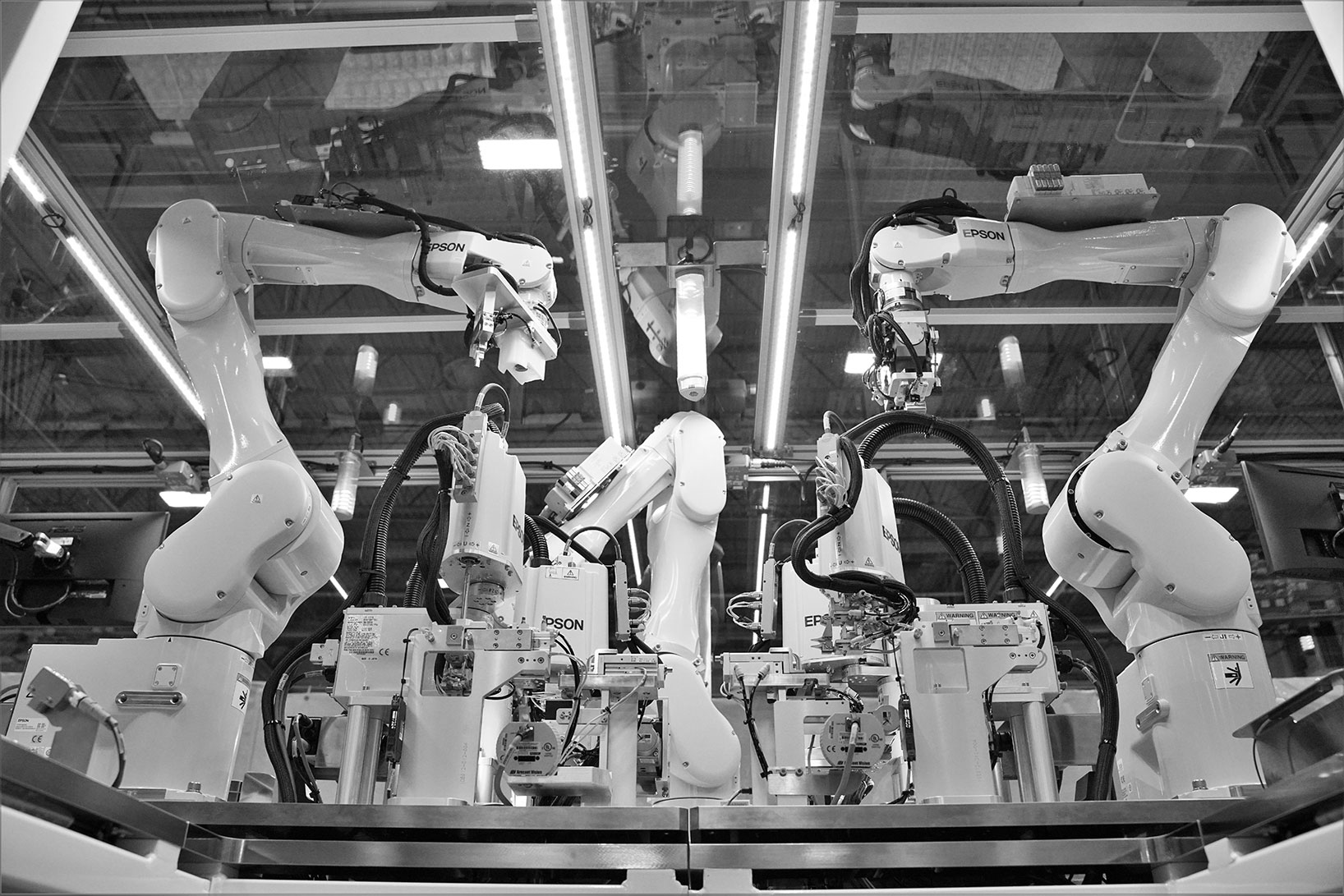

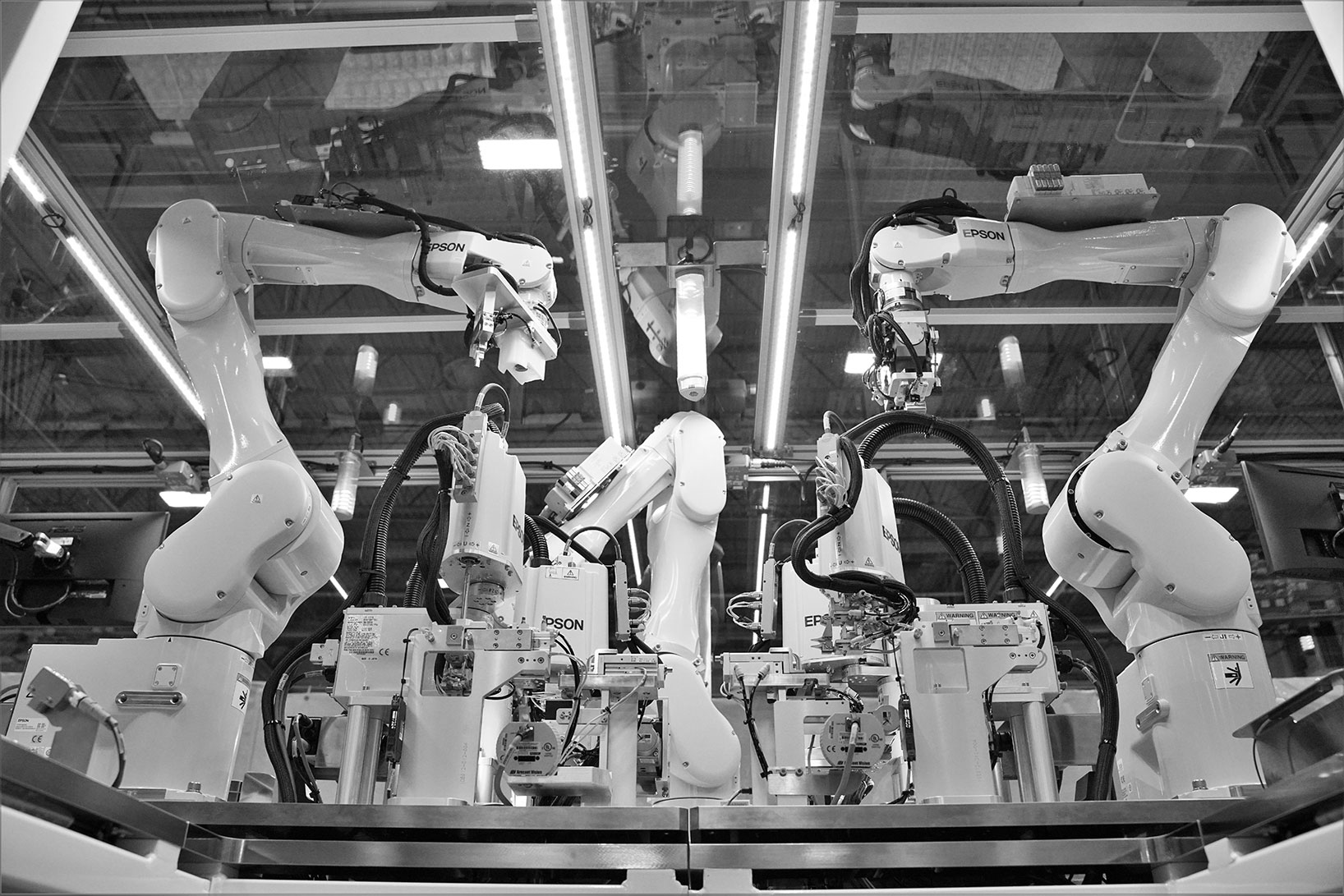

Automation NTH specializes in high-precision automation solutions, particularly for complex…

Automation NTH is proud to introduce our latest trade show…

2024 MedTech Summit Automation NTH invites you to the 2024…

When you work with Automation NTH, you’re not just investing…

Don’t Miss This Opportunity! Automation NTH is excited to announce…

Automation NTH recently participated in The Assembly Show South 2024.…

2024 ATX West Trade Show Booth #4515, Tray Loader Demo, Needle…

ATX News & Brews Video During ATX West, Peter Sarvey…

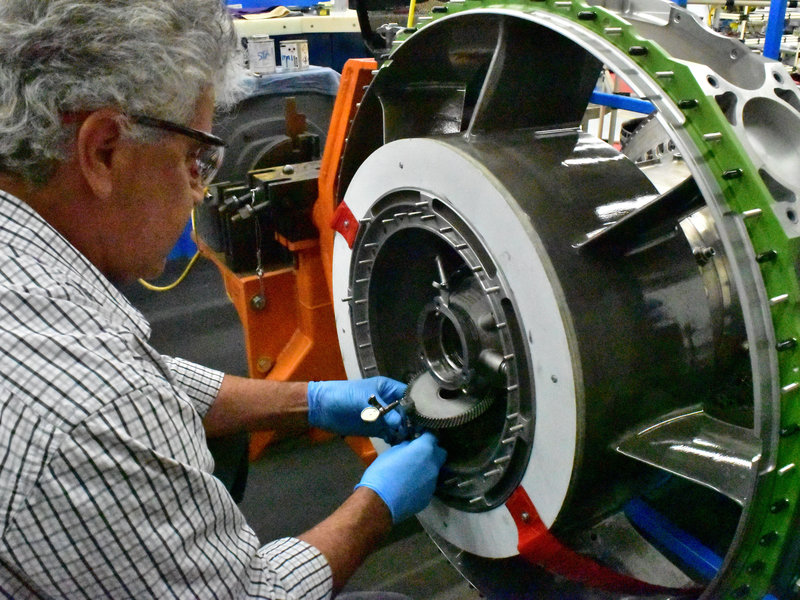

Industry: Automotive Location: La Vergne, Tennessee Customer Objectives: Inspect and…

Version control software allows manufacturers to automatically save code revisions…

As the requirements for robust industrial automation becomes more demanding,…

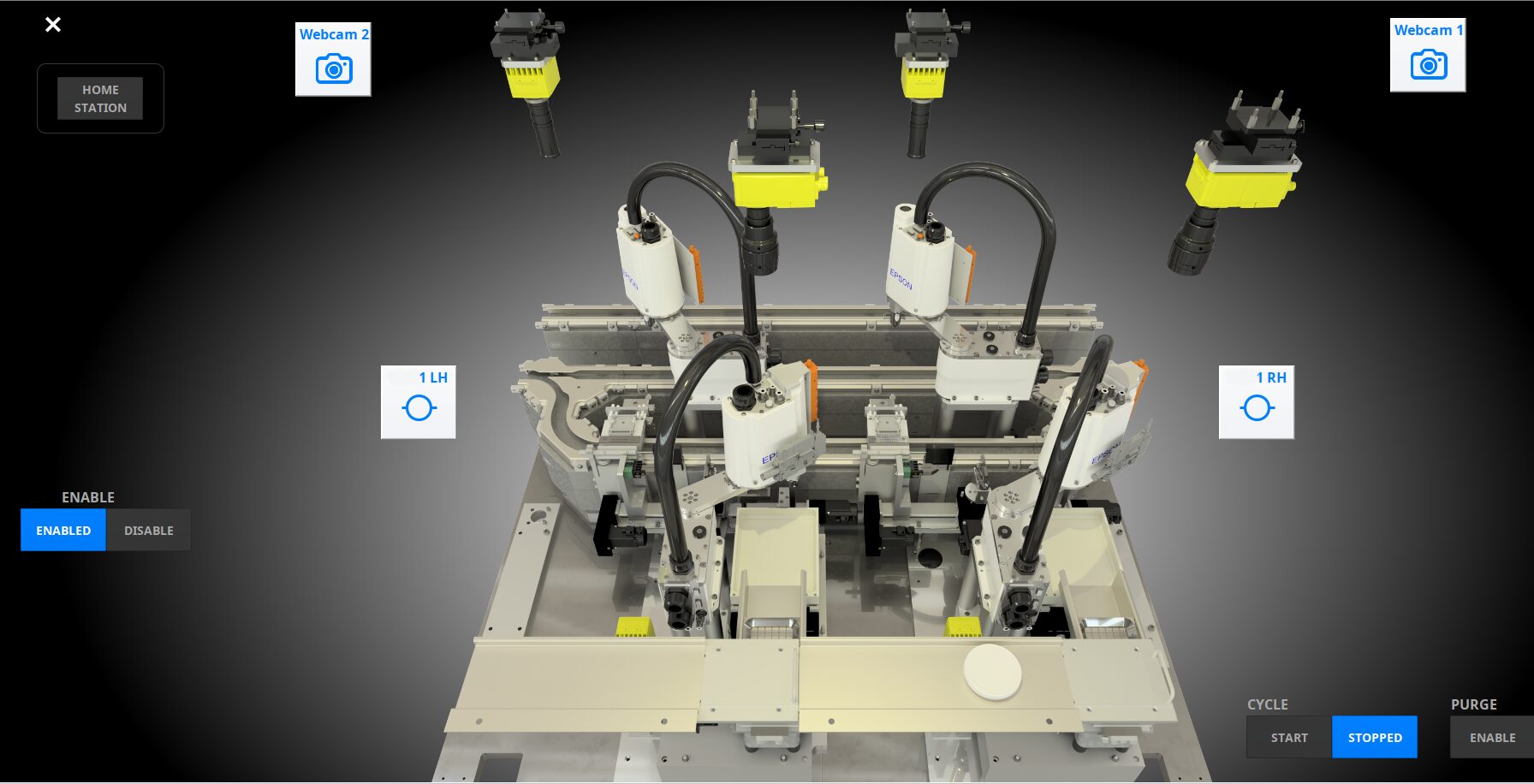

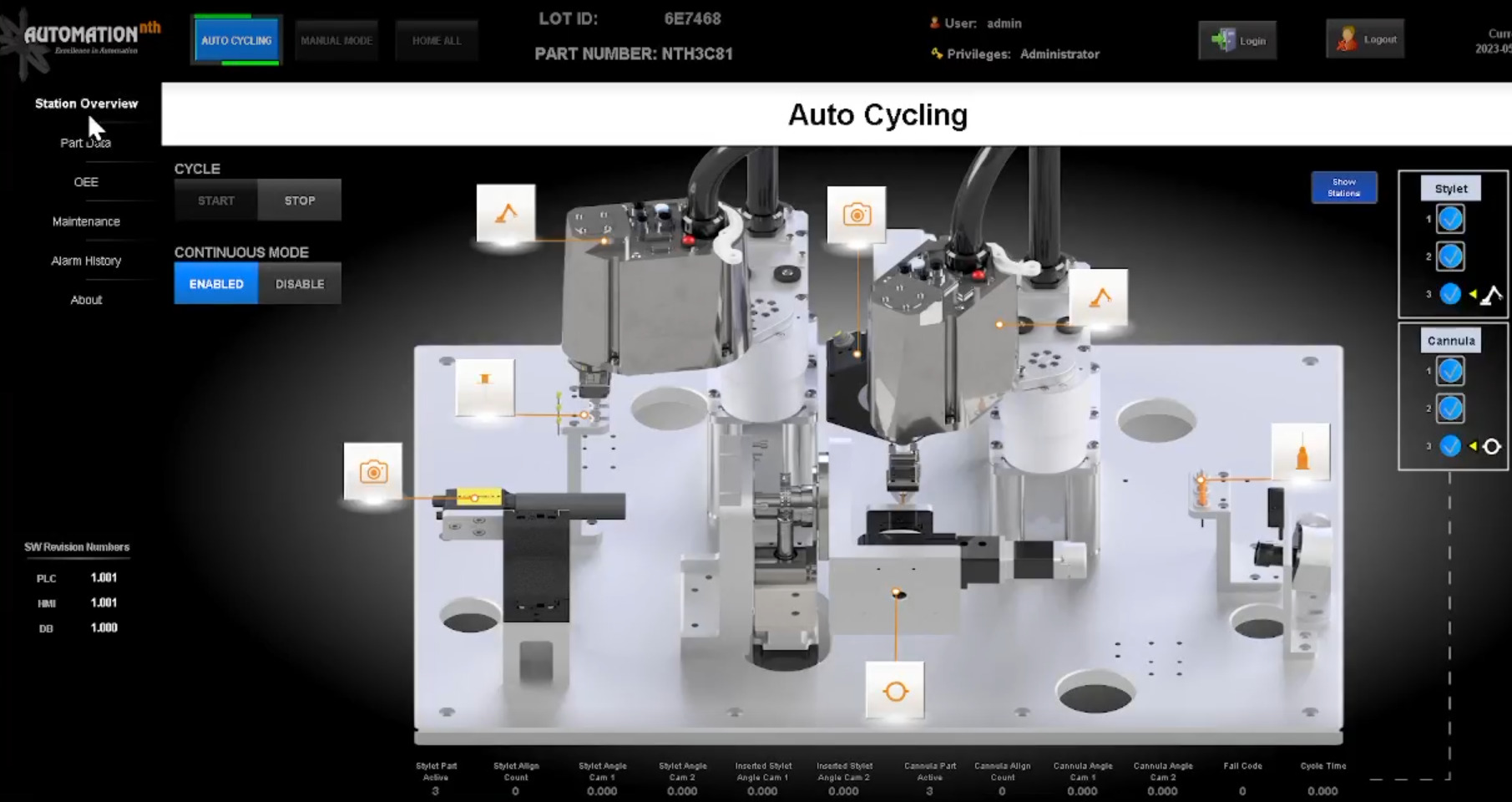

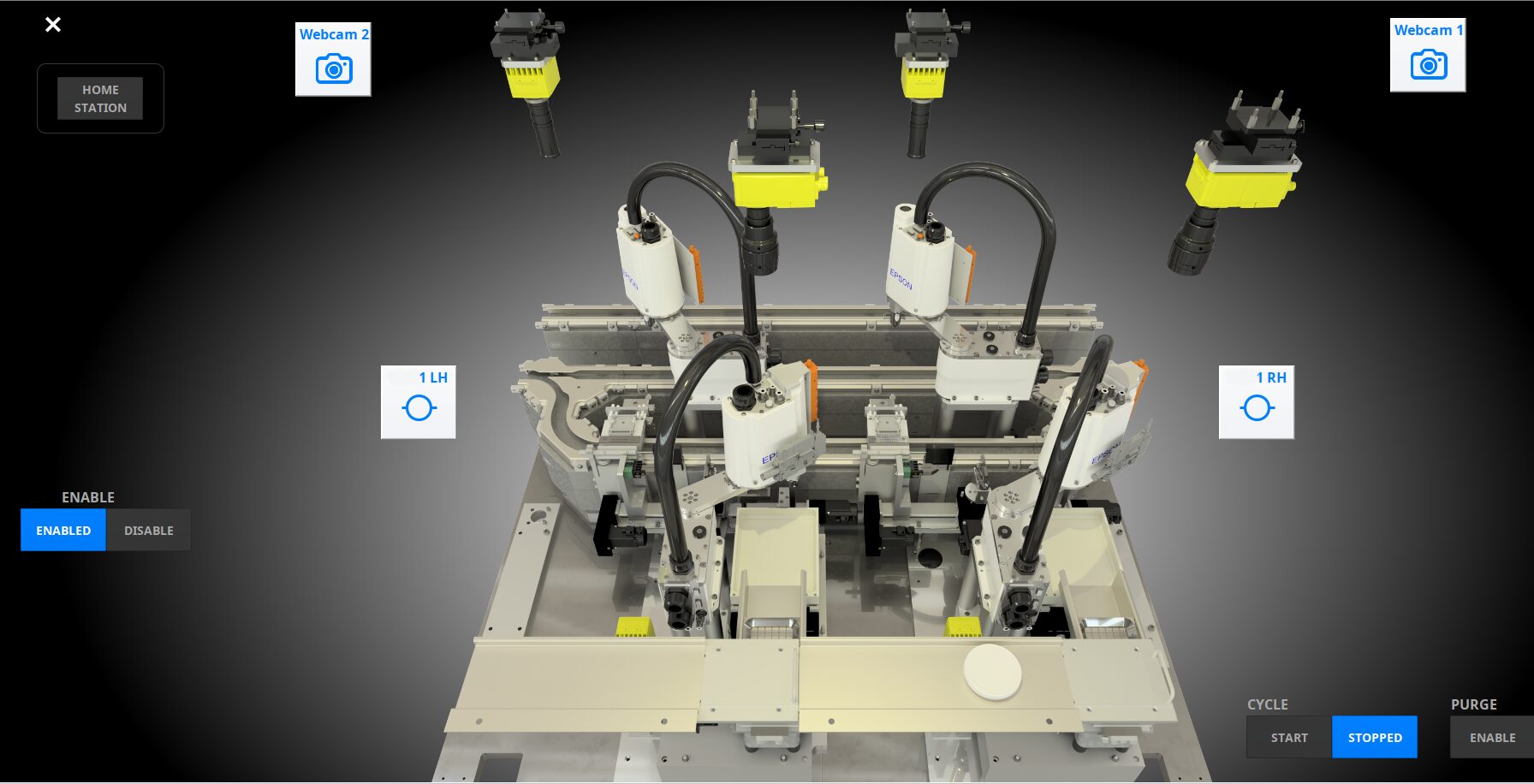

Station Control, a vital component of our industrial automation solutions,…

The Overview Screen is the gateway to all other functionality…

THE SITUATION: A global leader in eye care device manufacturing…

We are excited to announce a transition in our leadership…

After 24 years of leadership, Brent Thomas, Founder and President…

Automation NTH is proud to announce our recent achievement of…

Automation NTH's Customer Success Organization offers proactive support, optimization, training,…

Automation NTH is pleased to announce that after rigorous testing,…

Learn what makes a great HMI screen for industrial automation…

See how a medical device manufacturer partnered with Automation NTH…

Learn about the impressive technical challenges Automation NTH solved in…

Automation NTH uses streamlined processes and comperehensive support to accelerate…

Learn about technologies that characterize modern manufacturing practices.

NTH University accelerates automation skill acquisition for our engineers and…

A medical device manufacturer needed a turnkey automation solution for…

Why fix what is not broken? That’s a common sentiment…

How Custom Automation Can Improve Quality, Increase Efficiency, and Reduce…

Purchasing automation equipment is challenging. Step 4 describes how Automation…

Step 7 examines project execution and its typical project tasks,…

Step 8 examines the process for a Factory Acceptance Test,…

Step 9 discusses how to train operator and maintenance personnel…

Step 10 reviews how the equipment is installed and started…

After the equipment enters production there will still be issues…

We frequently get asked how Automation NTH‘s unique business model…

We are excited to announce that Automation NTH has been…

Automation NTH became Great Place to Work-Certified™ on February 1,…

Challenges with Quality Vision Inspection Systems Quality vision inspection systems…

Automation NTH will be exhibiting at the ATX West trade…

In order to compete globally, manufacturers need to constantly improve…

Automation Architects An industry leading Life Science company had been…

Automation NTH is proud to have been named 2020 System…

Automationnth recently celebrated its 20th anniversary since Automation NTH President…

We send out a monthly recap of what we've seen in…

Automationnth recently expanded its presence as a leading automation engineering…

Note: this public case study has removed sensitive details about…

There is no excerpt because this is a protected post.

The U.S. recently imposed a 25% tariff on steel imports…

We are pleased to announce that Automationnth has successfully achieved…

Automation NTH attended the ATX West and MD&M trade shows…

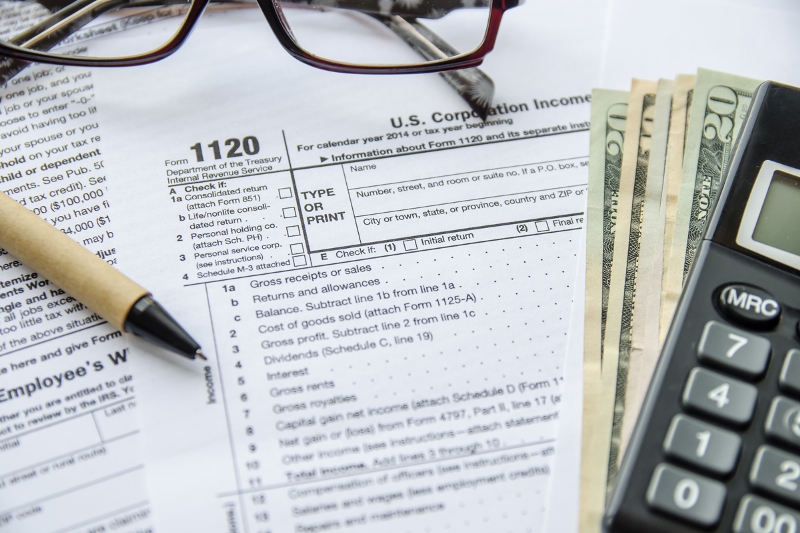

The recent tax reform legislation provides many benefits for manufacturers…

Situation A Fortune 50 company needed to create a custom…

Unplanned downtime can be a killer for manufacturing costs. Predictive…

Allen-Bradley Ultra3000 Servo Drives were discontinued by Rockwell at the…

There is one refrain we hear more often from our…

Ransomware and cyber attacks at manufacturers is becoming increasingly common,…

Download our comprehensive guide to learn more about how to create a successful automated manufacturing system for your organization.

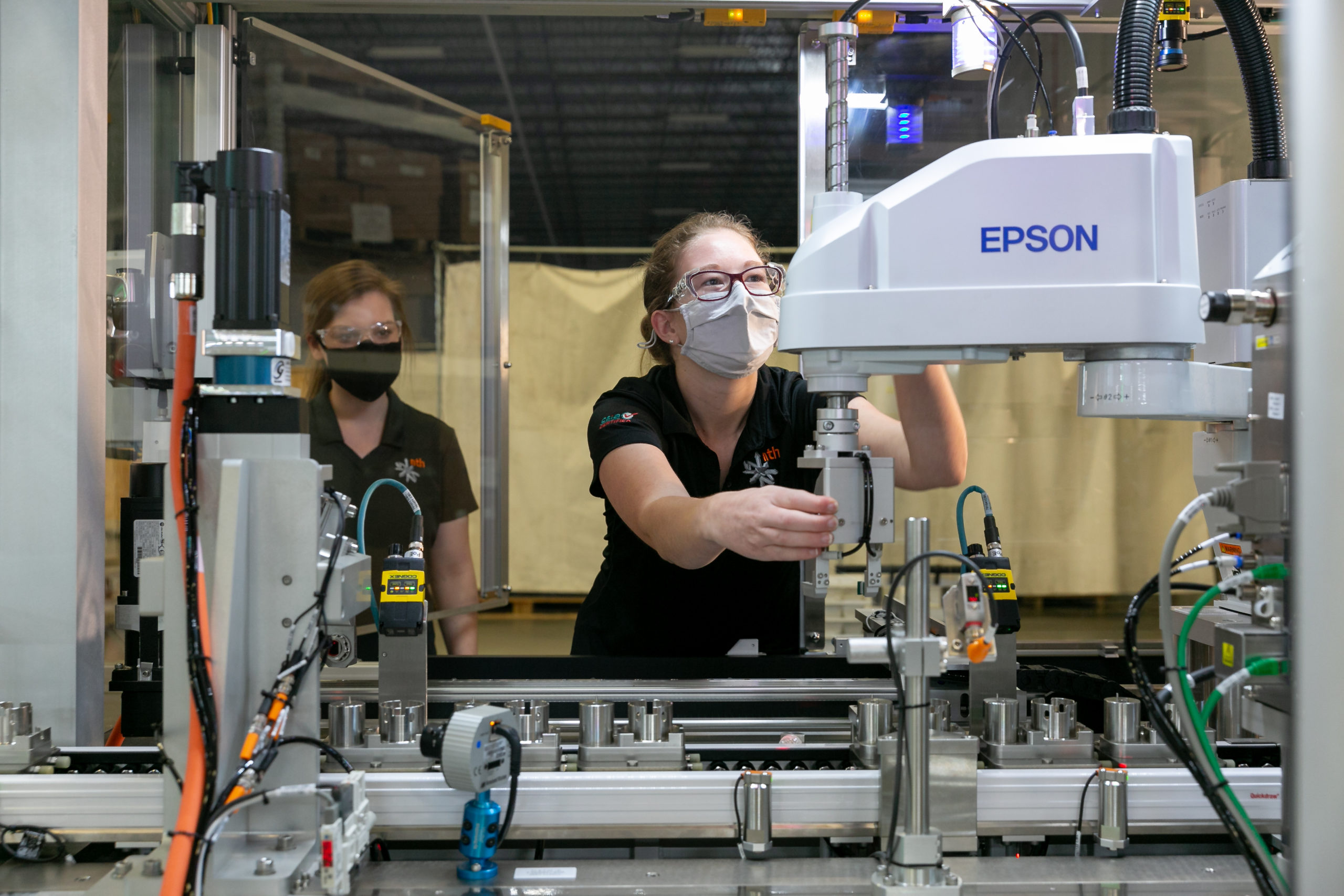

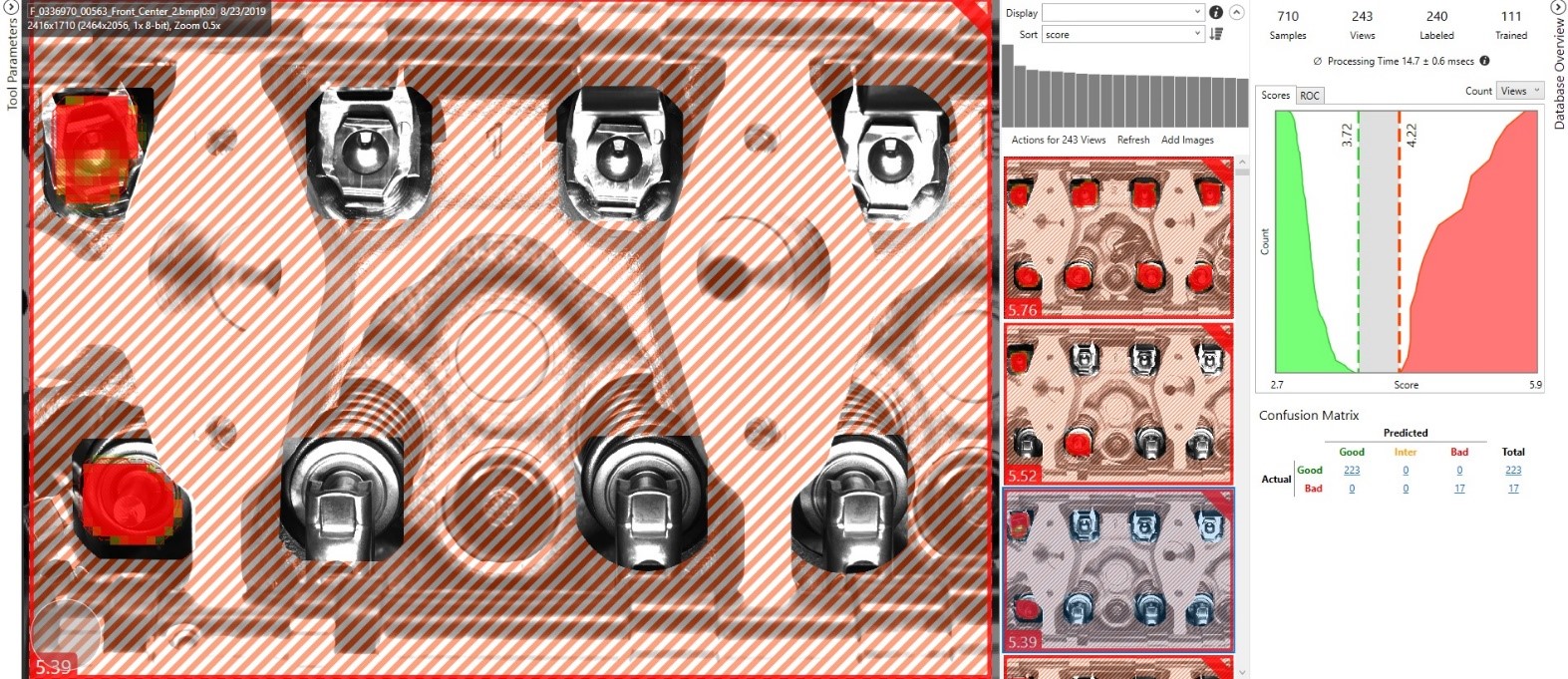

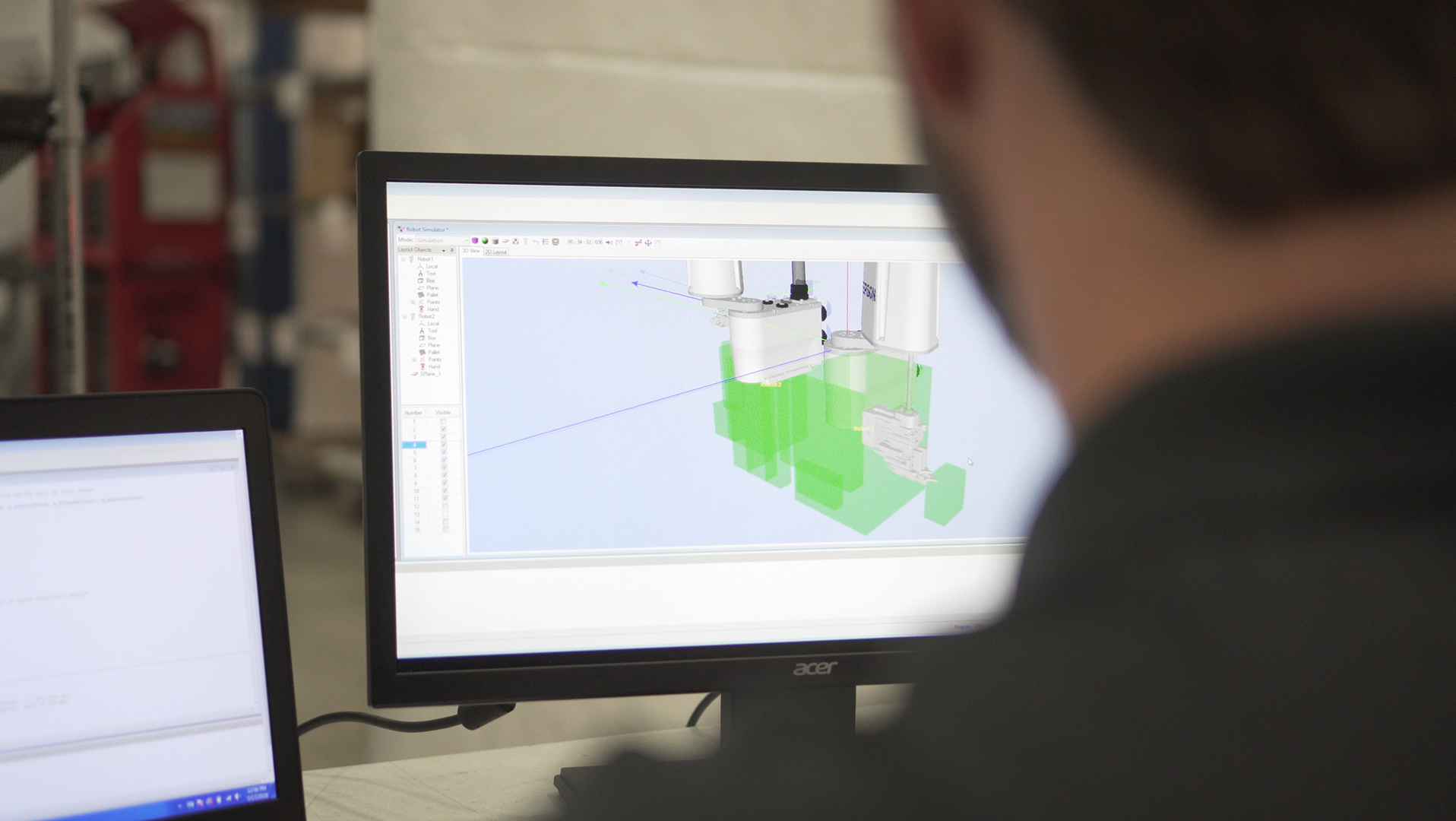

AI-driven vision inspection systems are reshaping quality control in modern manufacturing. These technologies expand the possibilities of automated inspection by offering adaptability, scalability, and the ability to recognize complex patterns beyond the reach of traditional rule-based systems. Overview A global

https://www.automationnth.com/wp-content/uploads/2025/11/drug-delivery-device-autoinjector.mp4

https://www.automationnth.com/wp-content/uploads/2025/11/drug-delivery-device-dispense-and-cure-application-video.mp4

Vision-Triggered Adhesive Jetting Cell Demonstrates Geometric Control and Robust Bonding for Precision Medical Assembly The proof-of-principle (POP) system was developed to evaluate whether UV-curable adhesive could be precisely jetted to form a functional geometric profile and a structurally sound bond

Automated Glue Dispense and Cure System Enhances Wearable Medical Device Assembly Production with 15s Cycle Time and Vision-Guided Precision. A leading medical device manufacturer partnered with Automation NTH to optimize the adhesive application process for a wearable medical device. The

A leading Medical Device manufacturer approached Automation NTH with the need for a semiautomated Machine that winds various Nitinol wires around a irregular shaped mandrels. The machine needed to handle multiple different products all with a sub 1 mm pitch

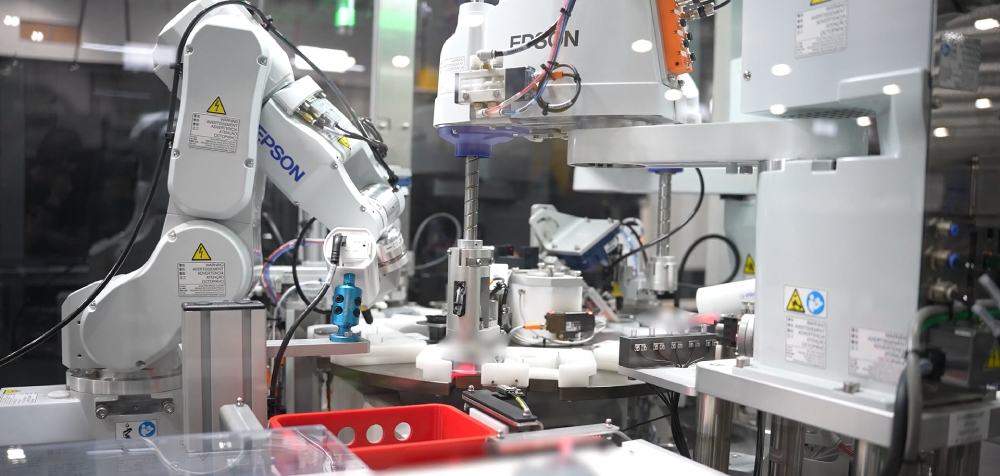

Hamilton Medical Inc., a global leader in ventilator and respiratory care device manufacturing, partnered with Automation NTH to address rising demand following the exit of two major competitors in the market. The company sought a fully automated solution to meet

A leading pharmaceutical manufacturer approached Automation NTH with the need for an automated Tray-to-Tub Cell to streamline their pre-filled syringe handling process. The project required a solution that could meet strict performance, footprint, and handling requirement. The manufacturer faced challenges

Beyond Our Walls: How Automation NTH Customers Can Drive Success with Data-Driven Gemba Walks Driven by a commitment to “excellence in automation,” we continuously refine our approach to project execution to deliver maximum value to our customers. A cornerstone of

Automation NTH tackled a medical device manufacturer’s challenge of scaling production while reducing costs and maintaining FDA compliance through their 30 step process for their device assembly system. After determining the production costs of the assembly process were driven by

Automation NTH has integrated a magnetic-levitation (maglev) system, XPlanar from Beckhoff Automation, into its flexible assembly machine for filling, inspecting, and sealing blood test kits. By using maglev technology, the system floats workpieces on a magnetic field, enabling precise movement

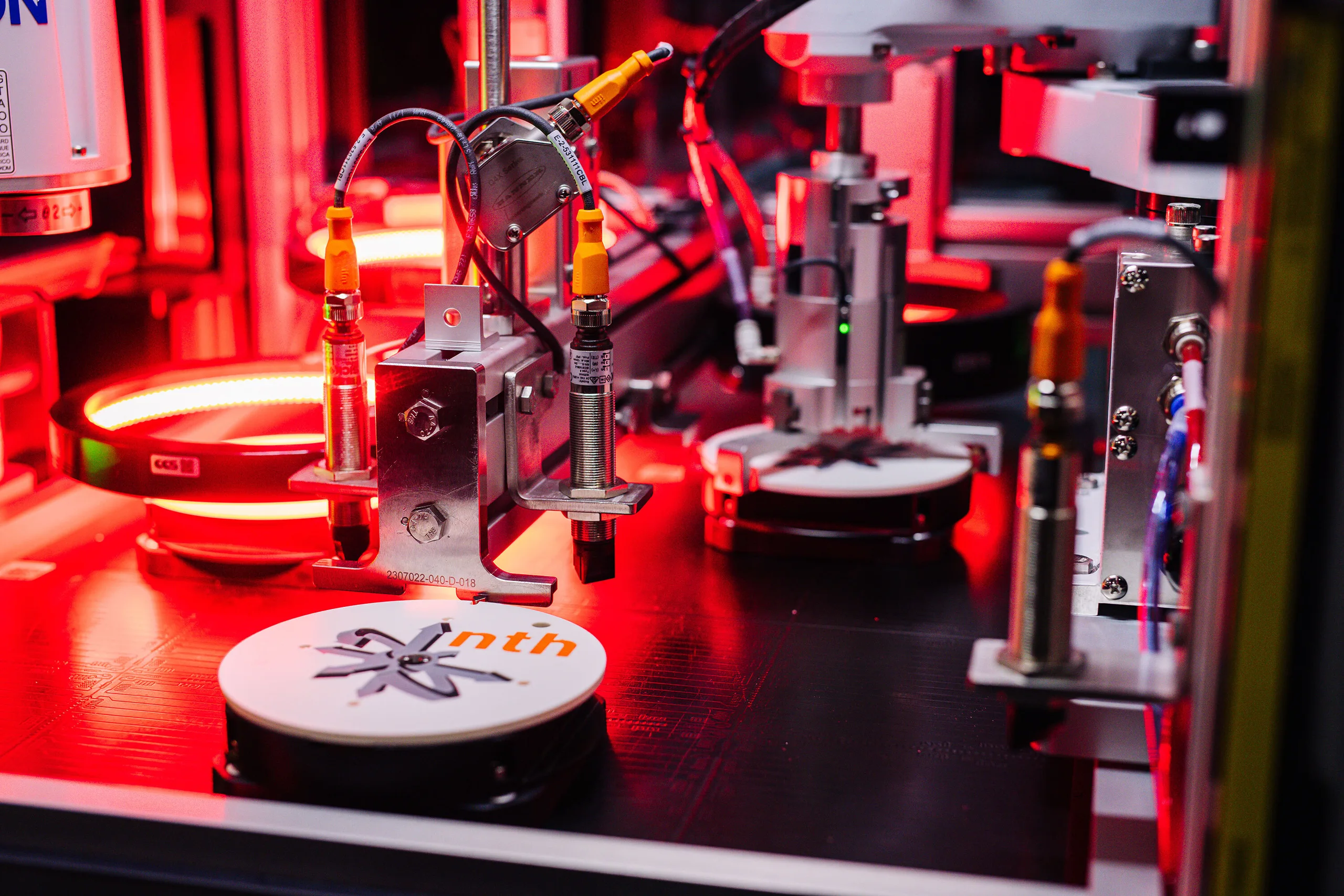

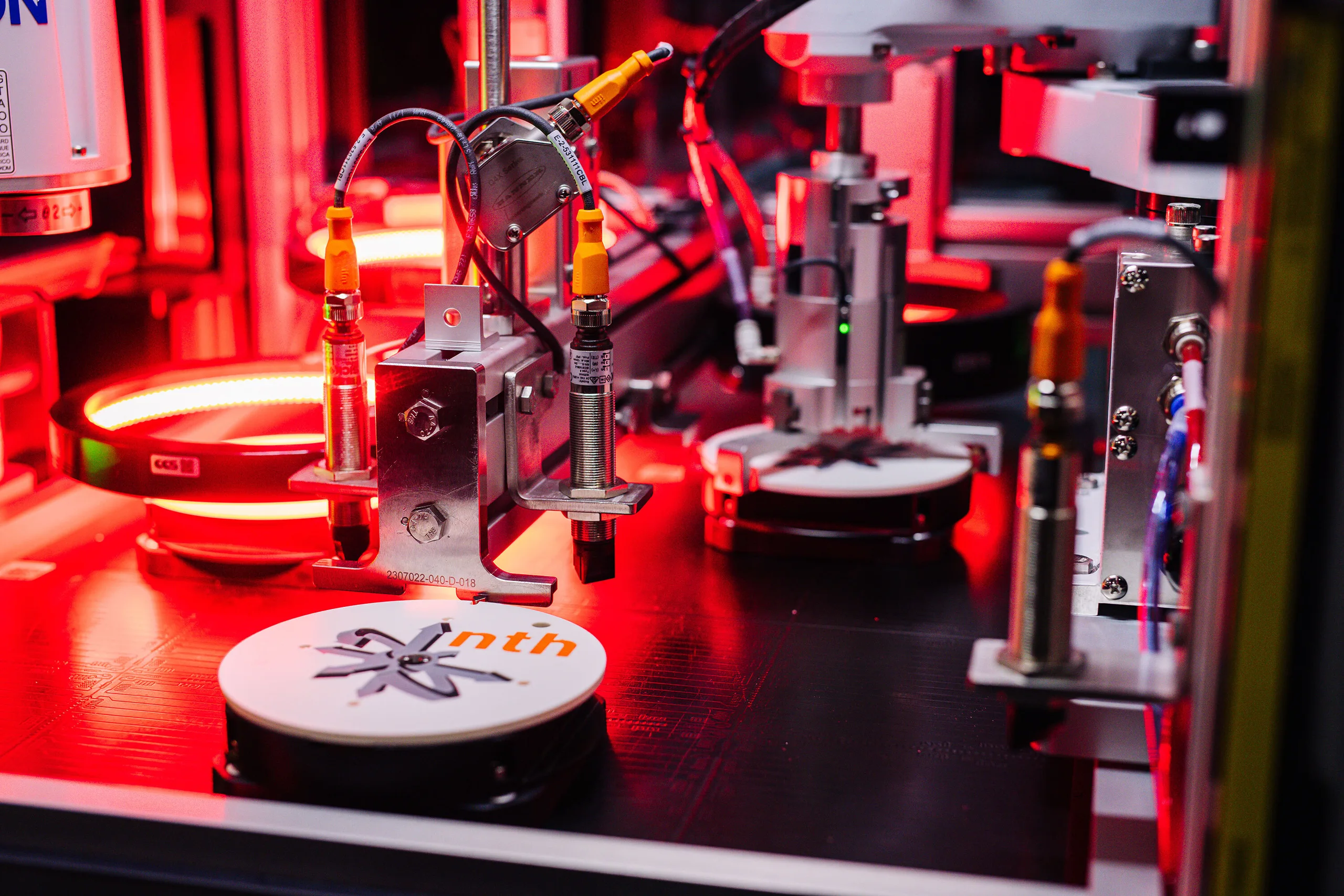

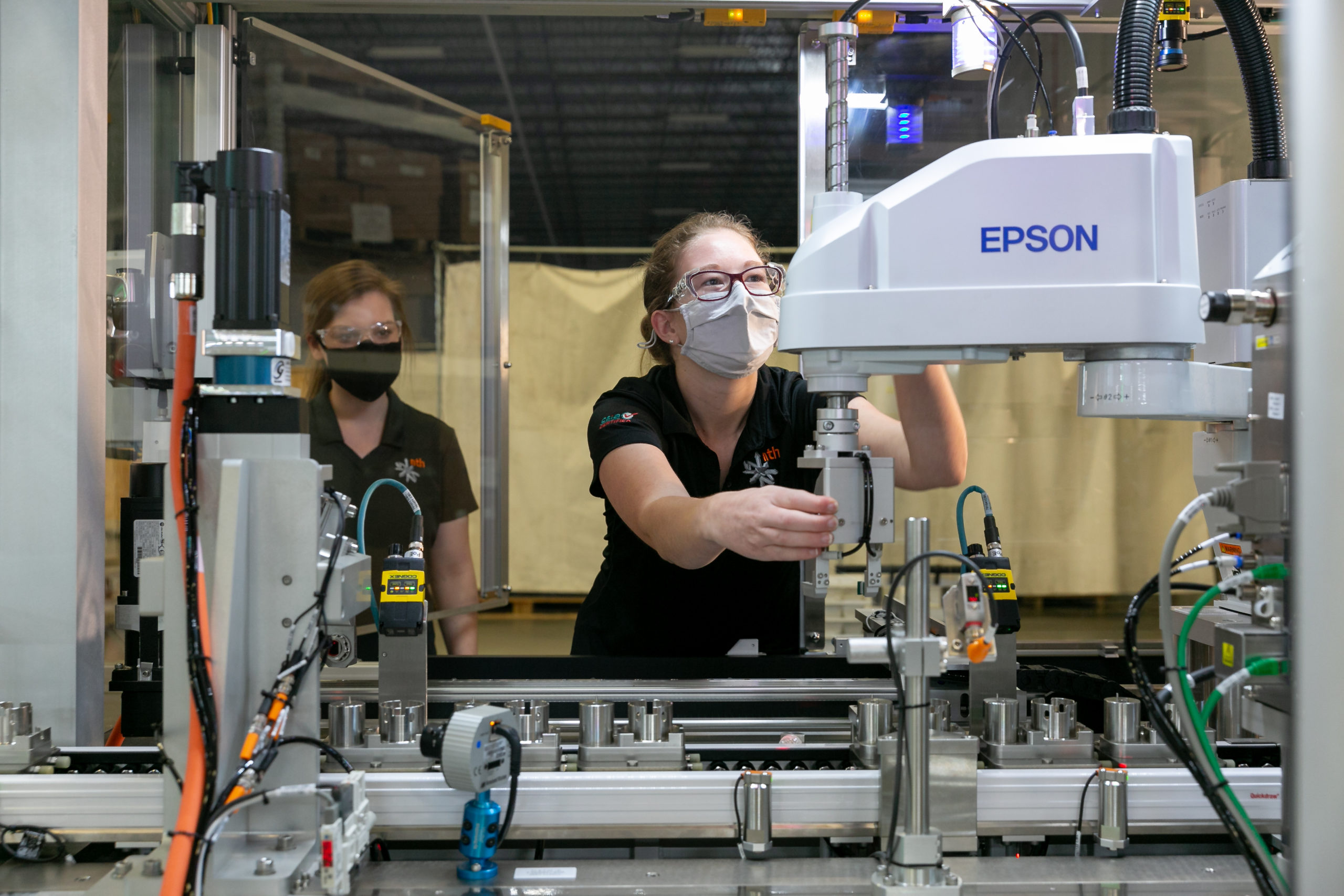

Automation NTH specializes in high-precision automation solutions, particularly for complex manufacturing challenges in the medical device and life sciences industries. When a diagnostics device manufacturer needed to transition from manual assembly to an advanced automated system, Automation NTH engineered a

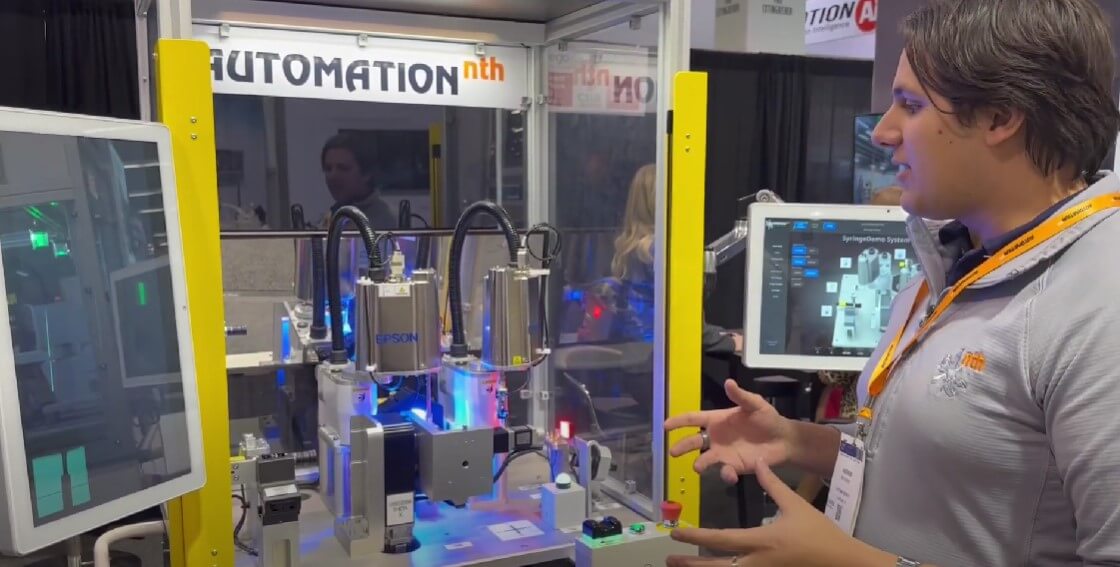

Automation NTH is proud to introduce our latest trade show machine: Diagnostic Test Assembly Cell (DTAC). Designed to showcase our expertise in delivering compact, efficient, and cutting-edge automation solutions, DTAC represents the pinnacle of automation technology for the Life Sciences

2024 MedTech Summit Automation NTH invites you to the 2024 MedTech Summit, where leading experts in the MedTech manufacturing field will discuss how automation is transforming the industry. Whether you’re starting your automation journey, planning for future needs, or scaling

When you work with Automation NTH, you’re not just investing in cutting-edge Automation Equipment; you’re partnering with a team dedicated to your long-term success. Our Customer Success Organization (CSO) is here to provide comprehensive, ongoing support that goes beyond service

Don’t Miss This Opportunity! Automation NTH is excited to announce our participation in the ATX South 2024 trade show, taking place from June 4-6, 2024, at the Charlotte Convention Center in Charlotte, North Carolina. Be sure to visit us at

Automation NTH recently participated in The Assembly Show South 2024. Taking place on May 1-2, 2024, at the Music City Center in Nashville, Tennessee, the event was a great and dynamic platform for industry leaders, experts, and enthusiasts to converge

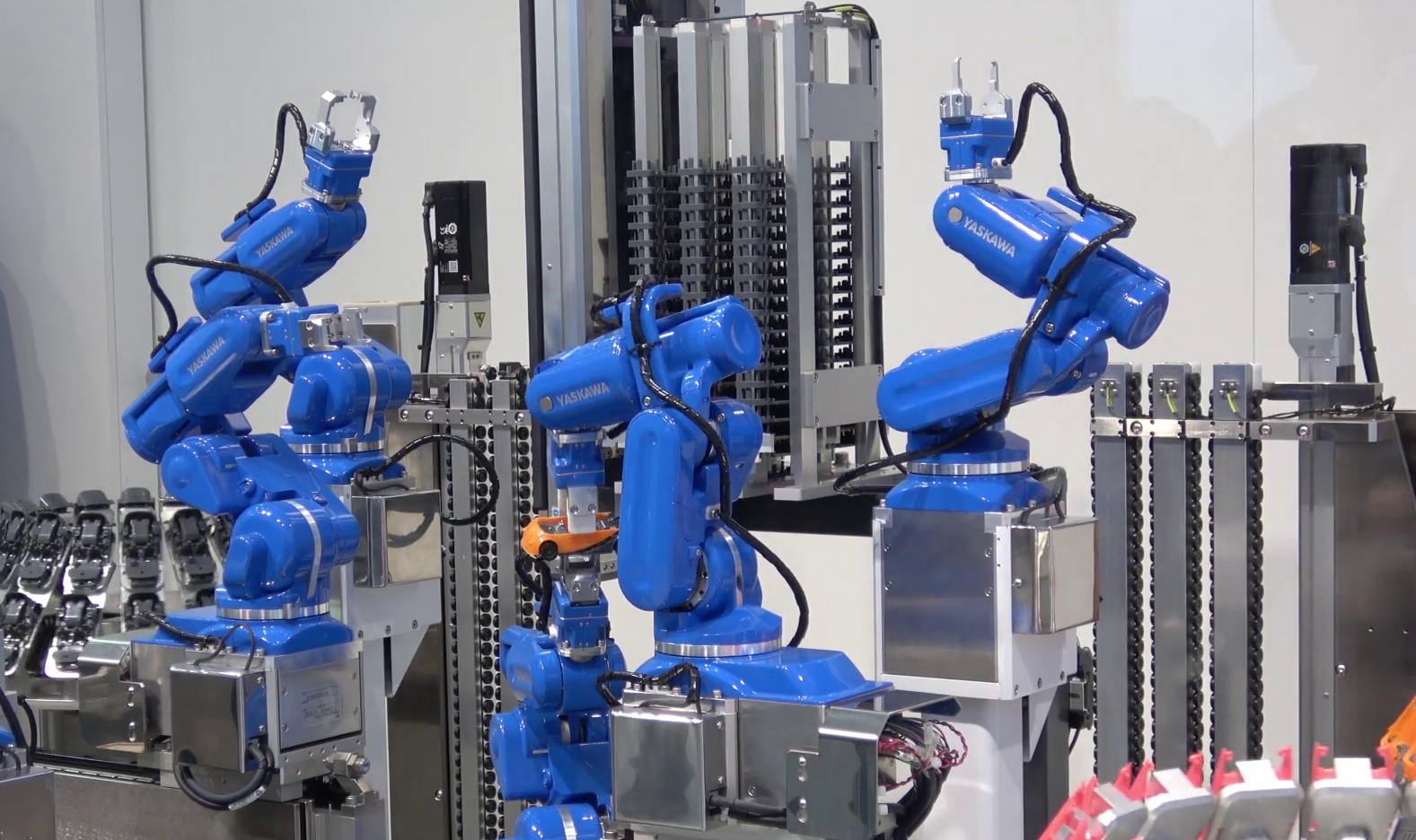

2024 ATX West Trade Show Booth #4515, Tray Loader Demo, Needle Assembly Demo, Robotic Pick & Place Demo. Vision Guided Robotics, Small Part Assembly, Part Inspection, Part Orientation, Wire Insertion, Medical Device, Life Science, Pharmaceuticals. FLEXBASE Platform: FLEXBASE Standard Automation Cell

ATX News & Brews Video During ATX West, Peter Sarvey had the opportunity to join Jacob (MFGKid) Sanchez on the Informa Markets – Engineering News & Brews stage to talk #OEE and Industrial Automation Equipment. To learn more about the Automation

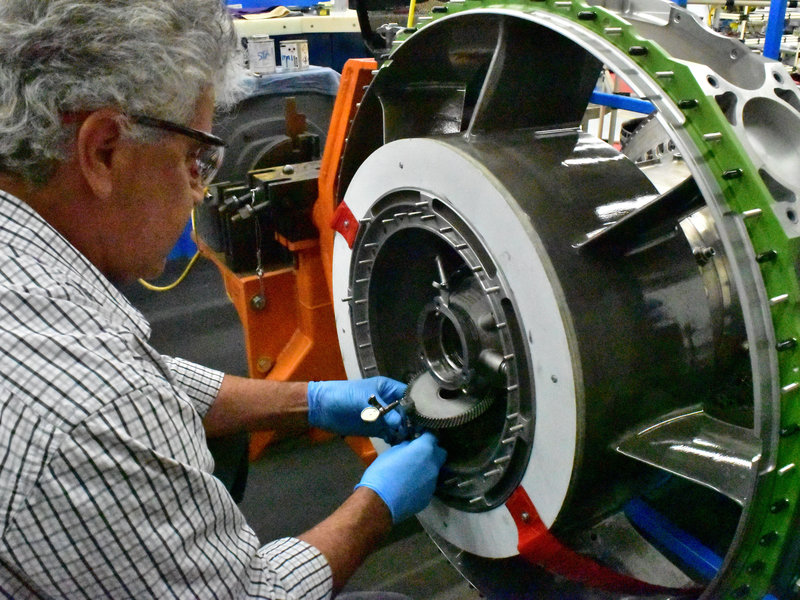

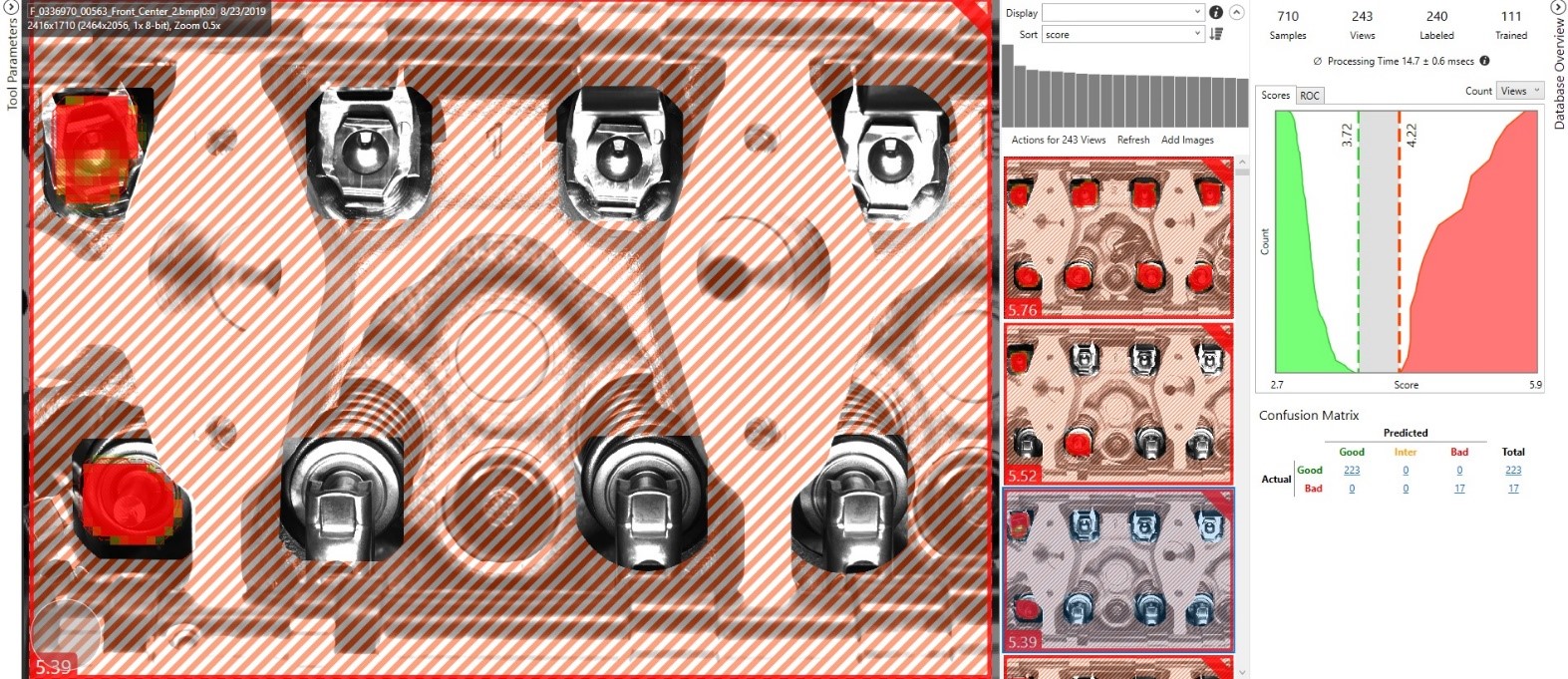

Industry: Automotive Location: La Vergne, Tennessee Customer Objectives: Inspect and verify clip placement in an engine block Account for issues such as oil, water, paint, and reflective surfaces that complicate image formation Key Results: Reduced scrap rates by separating cosmetic

Version control software allows manufacturers to automatically save code revisions across teams. Learn how Automation NTH leveraged this strategy to save countless hours and increase reliability. Version control software allows manufacturers to automatically save each version of code that teams

As the requirements for robust industrial automation becomes more demanding, relying on traditional automation technology becomes less sufficient. The future of manufacturing lies in smart manufacturing automation, and NTH is at the forefront of this revolution. The industry’s accepted tools

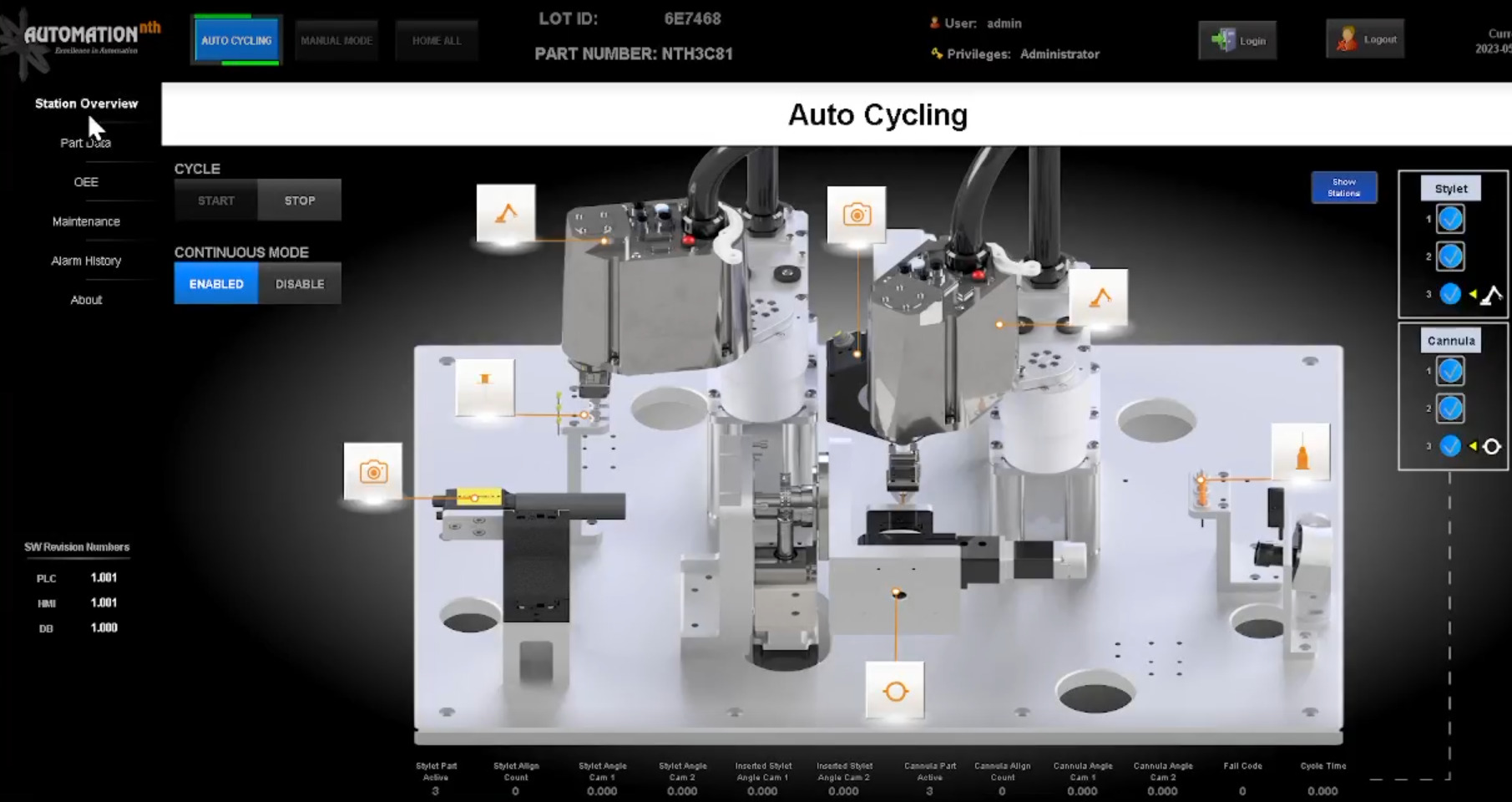

Station Control, a vital component of our industrial automation solutions, enables operators to isolate a single sub-assembly or station. The ‘Station’ definition varies across applications, but typically includes hardware chosen to perform a specific task controlled by a dedicated set

The Overview Screen is the gateway to all other functionality of the HMI application, providing essential access points for automated control systems. Global information is pinned at the top of the monitor, and attention is drawn to critical information, a

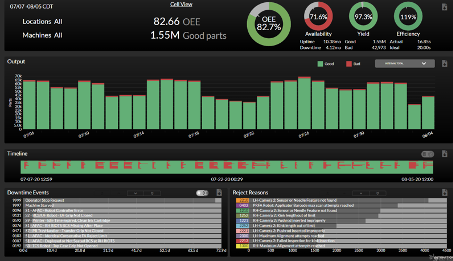

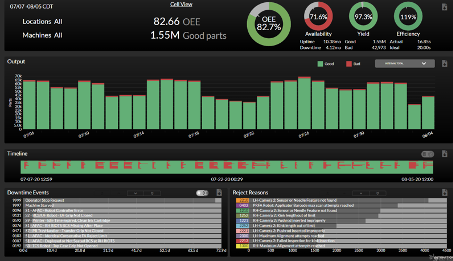

THE SITUATION: A global leader in eye care device manufacturing approached Automation NTH to help provide a solution to its “information overload” on the manufacturing floor. As this customer grew, their manufacturing equipment multiplied, along with new processes and mountains

We are excited to announce a transition in our leadership at Automation NTH following the retirement of Automation NTH Founder Brent Thomas. Jeff Buck and Greg Young will lead the company as Co-Presidents, driving our company into its next chapter of innovation and growth.

After 24 years of leadership, Brent Thomas, Founder and President of Automation NTH, is retiring on December 8th, 2023.

Automation NTH is proud to announce our recent achievement of the ISO 9001:2015 certification. This important milestone reflects our commitment to maintaining high quality standards in our products and services.

Automation NTH’s Customer Success Organization offers proactive support, optimization, training, and tailored engagement. Services are designed to keep custom automation equipment at peak performance, minimizing downtime and maximizing quality and productivity.

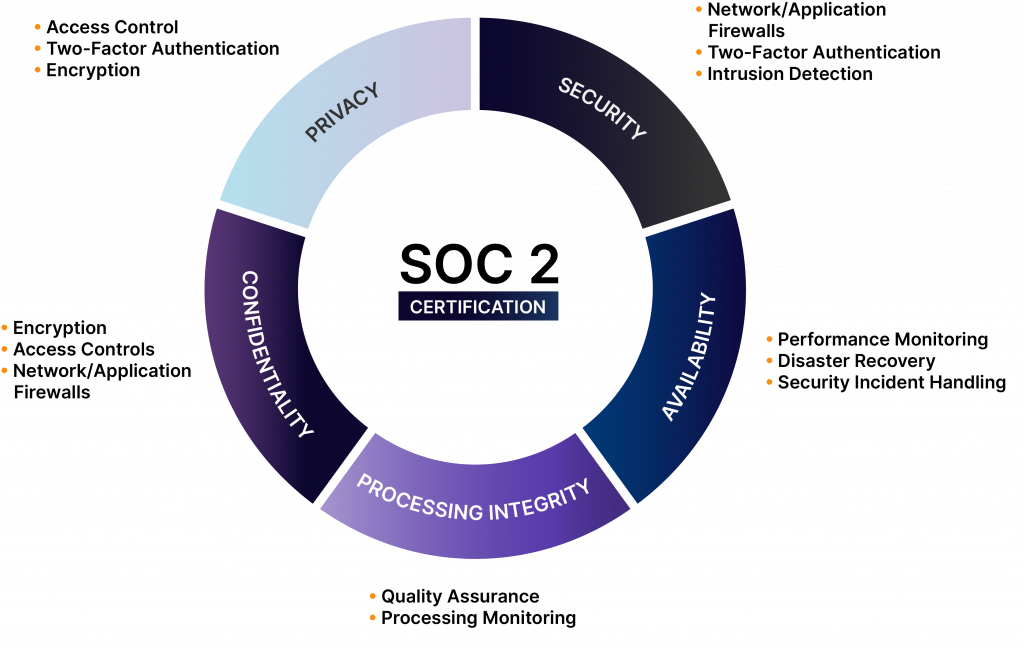

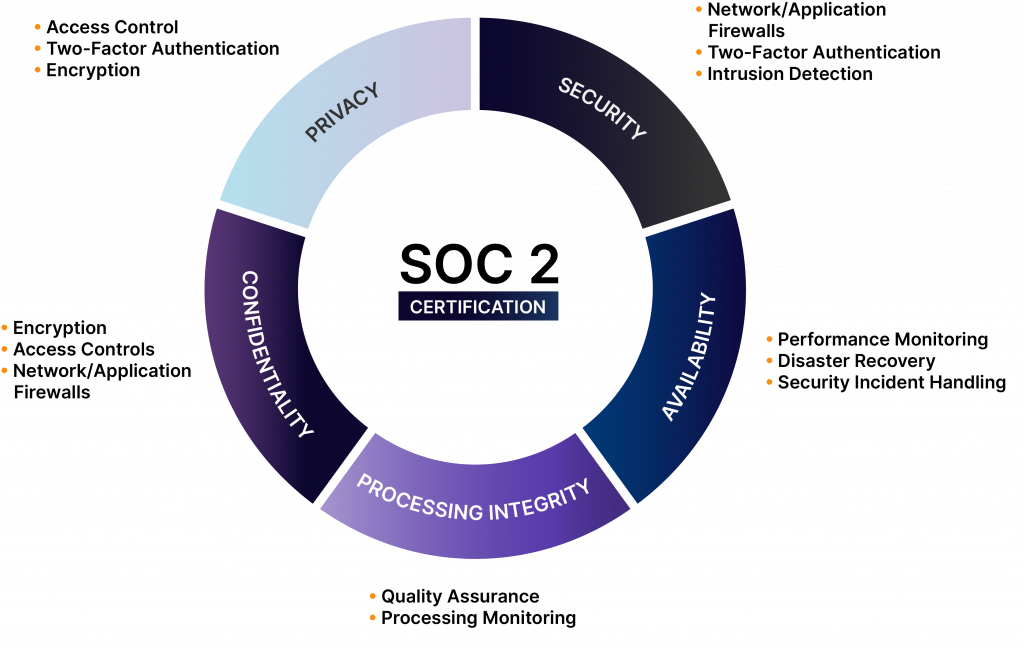

Automation NTH is pleased to announce that after rigorous testing, tuning, and refinement, it has successfully achieved the SOC 2 certification.

Learn what makes a great HMI screen for industrial automation equipment and the design principles Automation NTH uses for its HMIs.

See how a medical device manufacturer partnered with Automation NTH to drive continuous improvement on their equipment with OEE Optimizer and a Pareto Busters initiative.

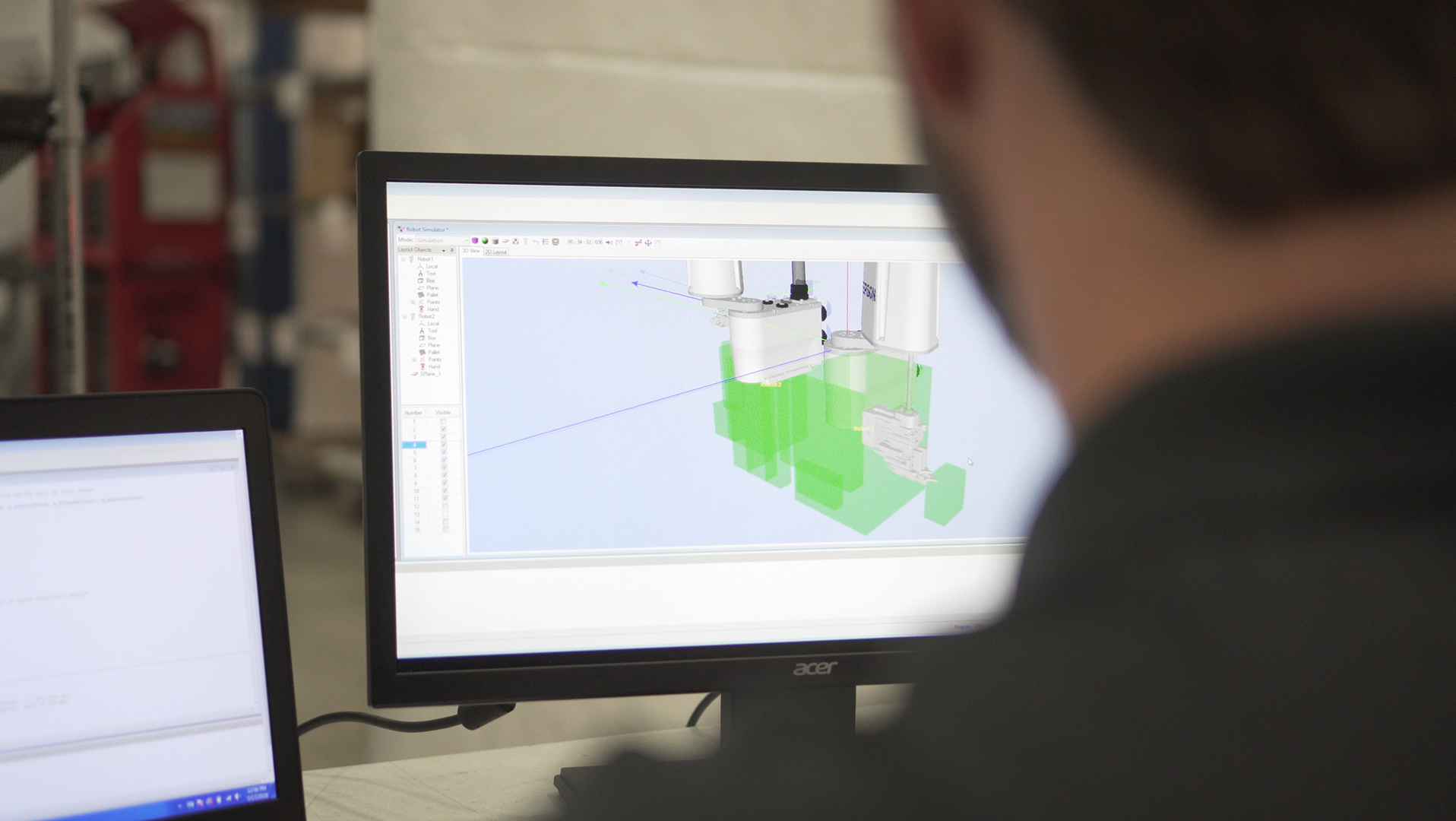

Learn about the impressive technical challenges Automation NTH solved in order to create its vision guided robotic wire insertion demo machine, which you can see in person when we exhibit at trade shows.

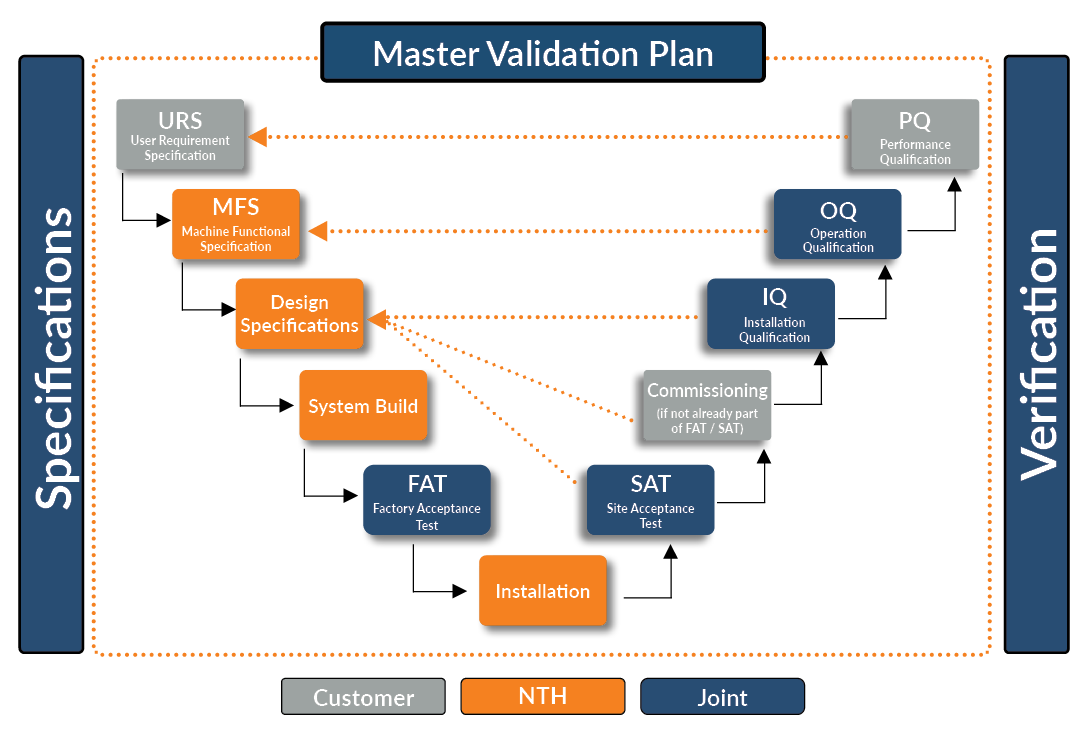

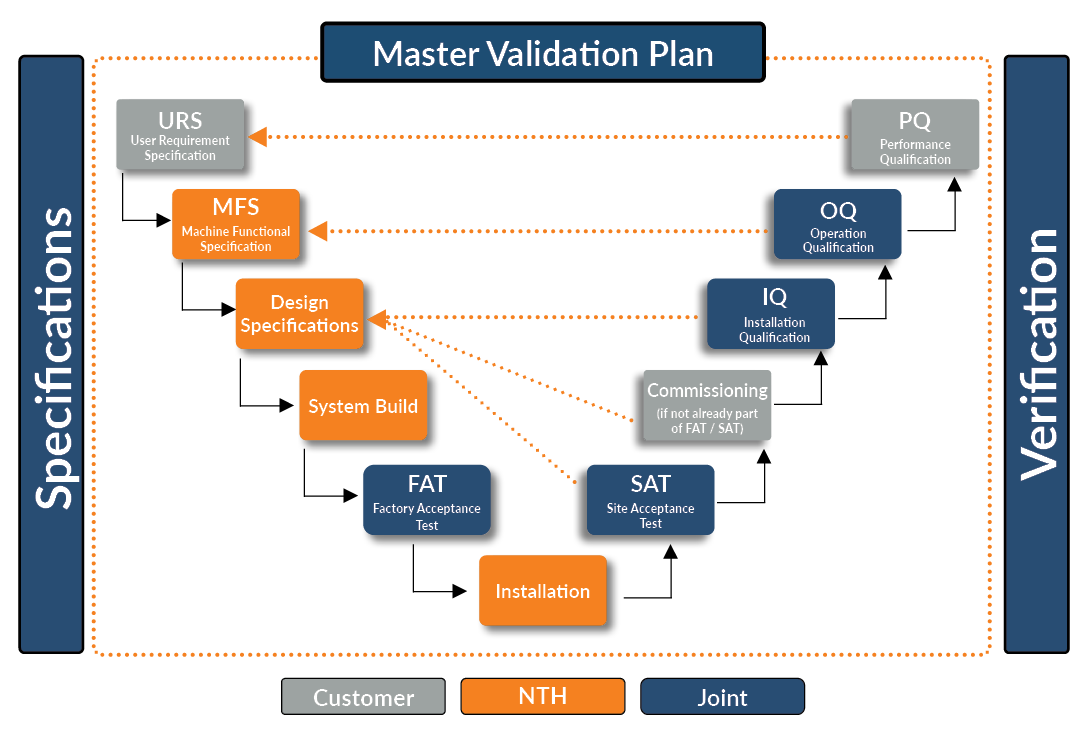

Automation NTH uses streamlined processes and comperehensive support to accelerate the successful GAMP validation of automation systems for Life Science manufacturers.

Learn about technologies that characterize modern manufacturing practices.

NTH University accelerates automation skill acquisition for our engineers and customers. Learn about 5 key elements of the program that make it so effective.

A medical device manufacturer needed a turnkey automation solution for filling, weighing, capping, labeling, and palletizing tubes filled with a chemical reagent. The product line contained more than 900 permutations of tube, cap, and label combinations.

Why fix what is not broken? That’s a common sentiment among traditional manufacturing leaders, but have you heard about the Industrial Internet of Things (IIoT)? But what if you could predict when something will break and address it during scheduled

How Custom Automation Can Improve Quality, Increase Efficiency, and Reduce Risk in Your Operations Technological advancements have improved quality and efficiency across industries, but automation in manufacturing has transformed how companies can manufacture their products. Automation equipment is a substantial

This is Step 1 in an 11 part series that shares insights about how manufacturers can successfully implement custom automated systems.

Step 2 describes the role of an automation architect and the initial steps to take after hiring an automation architect.

Step 3 discusses how to create the right team to plan, implement, and operate automation. Learn about key roles and when to engage them.

Purchasing automation equipment is challenging. Step 4 describes how Automation NTH helps manufacturers reduce risk in supplier selection.

Step 5 discusses how a contract helps set expectations clearly up front and reduces potential conflict as the machine enters production.

Step 6 discusses how the team analyzes the design of the product, required quality and production levels, acceptance criteria, and other requirements.

Step 7 examines project execution and its typical project tasks, project management, and factors that are critical to success during debug.

Step 8 examines the process for a Factory Acceptance Test, including how the timing of the test plays a critical role in equipment success.

Step 9 discusses how to train operator and maintenance personnel to ensure they succeed with the automation equipment.

Step 10 reviews how the equipment is installed and started up at a manufacturer’s facility.

After the equipment enters production there will still be issues to resolve and opportunities for optimization. Common issues include unplanned downtime, low yield, and slow cycle time.

We frequently get asked how Automation NTH‘s unique business model can possibly be cost competitive with vertically integrated machine builders.

We are excited to announce that Automation NTH has been recognized as one of America’s fastest growing privately held companies by Inc. Magazine. The Inc. 5000 list is a widely known annual publication that ranks companies by revenue growth. Automation

Automation NTH became Great Place to Work-Certified™ on February 1, 2020. 96% of our employees agree that it is a great place to work and 100% agreed that “our customers would rate the service we deliver as excellent.”

Challenges with Quality Vision Inspection Systems Quality vision inspection systems play a vital role in the production of automotive engines where cast and machined frames are matched and assembled with various vendor-supplied components. Slight defects in materials or incorrectly installed

Automation NTH will be exhibiting at the ATX West trade show at booth 4388 from Feb. 11-13, 2020, at the Anaheim Convention Center in Anaheim, California.

All custom automation projects carry some amount risk. Unexpected issues inevitably emerge over the course of a project and increase with the complexity of an application. An automation company that uses a rigorous methodology to assess and manage risk will

In order to compete globally, manufacturers need to constantly improve performance and efficiency in their plants. One potential source of competitive advantage that manufacturers often overlook is their relationship with system integrators. We believe that manufacturers who build deep, strategic

Good, experienced engineers are hard to find in the automation industry. Both manufacturers and system integrators struggle to hire enough engineers to keep up with demand. Hiring engineers straight out of school presents its own challenges, too. It typically takes

Some manufacturers spend millions of dollars on automation equipment but don’t have the information they need to maximize their return on this investment. These manufacturers suffer from a lack of insight into their production and supply chain that could be

Automation Architects An industry leading Life Science company had been trying to automate a key element of its product assembly for 7 years without success. Their product, a Class II medical device, requires a process to insert a component with

Automation NTH is proud to have been named 2020 System Integrator of the Year by CFE Media, the publisher of Control Engineering and Plant Engineering magazines. The award is

Automationnth recently celebrated its 20th anniversary since Automation NTH President Brent Thomas co-founded the company on November 1st, 1999. Brent was destined to become an entrepreneur. Growing up he started a landscaping business in high school and a computer repair

A customer in the software industry started with an ambitious goal: to make its first ever game controller and fully automate the production process. Starting with just an initial product concept and no idea how to make it, the customer engaged our machine builder partner and Automationnth to develop a manufacturing line.

We send out a monthly recap of what we’ve seen in manufacturing and automation news and thought was interesting. This post contains links to prior month’s newsletters.

Automationnth recently expanded its presence as a leading automation engineering company in Southern California by leasing a new 10,000 sq. ft. facility located at 12525 Kirkham Court in Poway, California. Located 20 miles from downtown San Diego and 90 miles

Note: this public case study has removed sensitive details about our customer and their product line. If you are interested in seeing the full machine vision case study with all the details including photos and videos, please contact us here.

There is no excerpt because this is a protected post.

The U.S. recently imposed a 25% tariff on steel imports and a 10% tariff on aluminum imports. Roughly one-third of the 100 million tons of steel used each year by American business is imported, while imports account for more than 90% of

We are pleased to announce that Automationnth has successfully achieved Control System Integrators Association (CSIA) certification through an external audit. The comprehensive CSIA Certification audit assessed Automationnth’s compliance with 76 criteria in the areas of project management, quality assurance, business

Automation NTH attended the ATX West and MD&M trade shows in Anaheim, California on February 8th to see the latest advances in automation technologies. This was a huge show with a lot to take in, but a consistent highlight for

The recent tax reform legislation provides many benefits for manufacturers in the U.S., who are just coming off the best year of factory activity since 2004. The elements of the legislation that have the most impact on manufacturers’ taxes include: Corporate

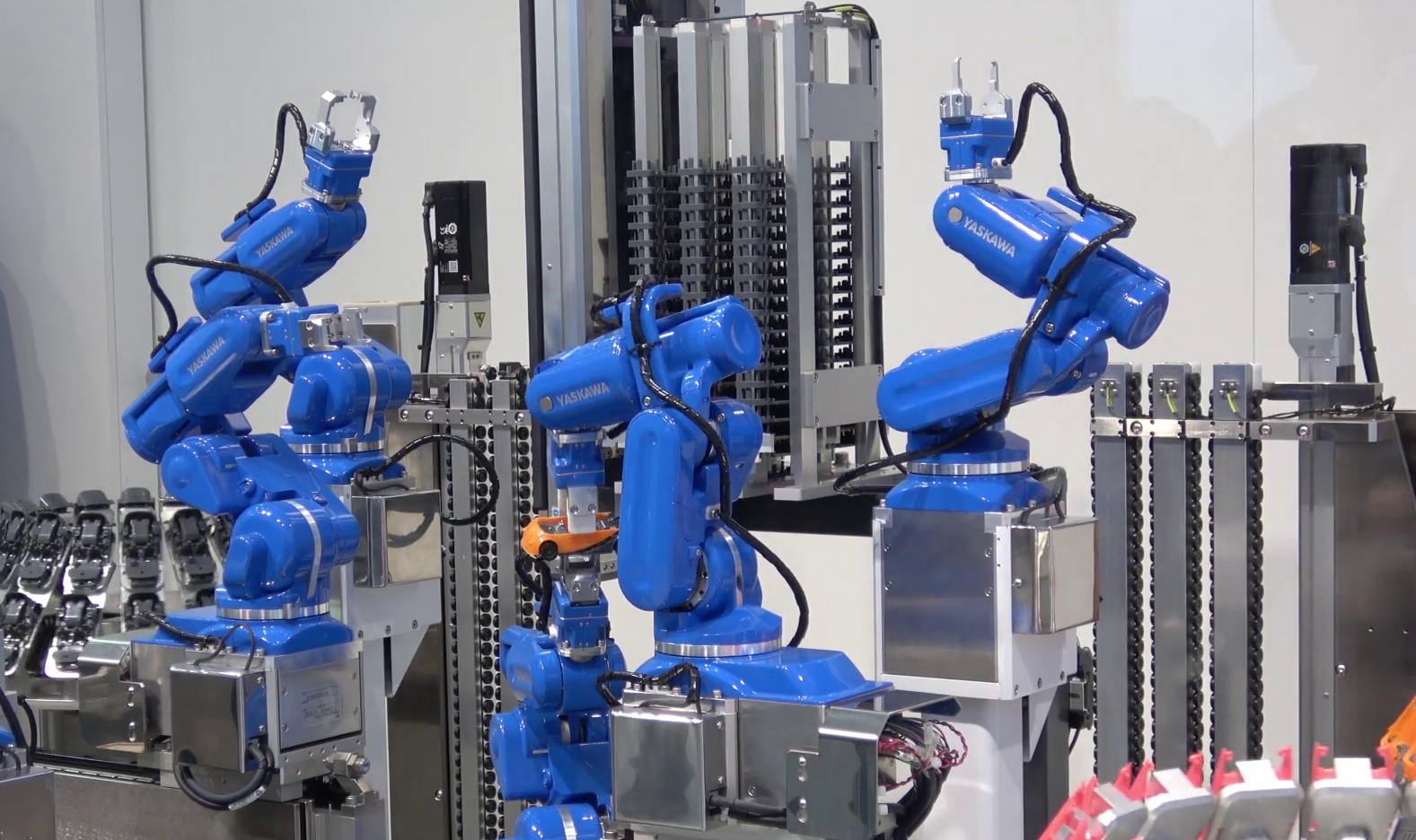

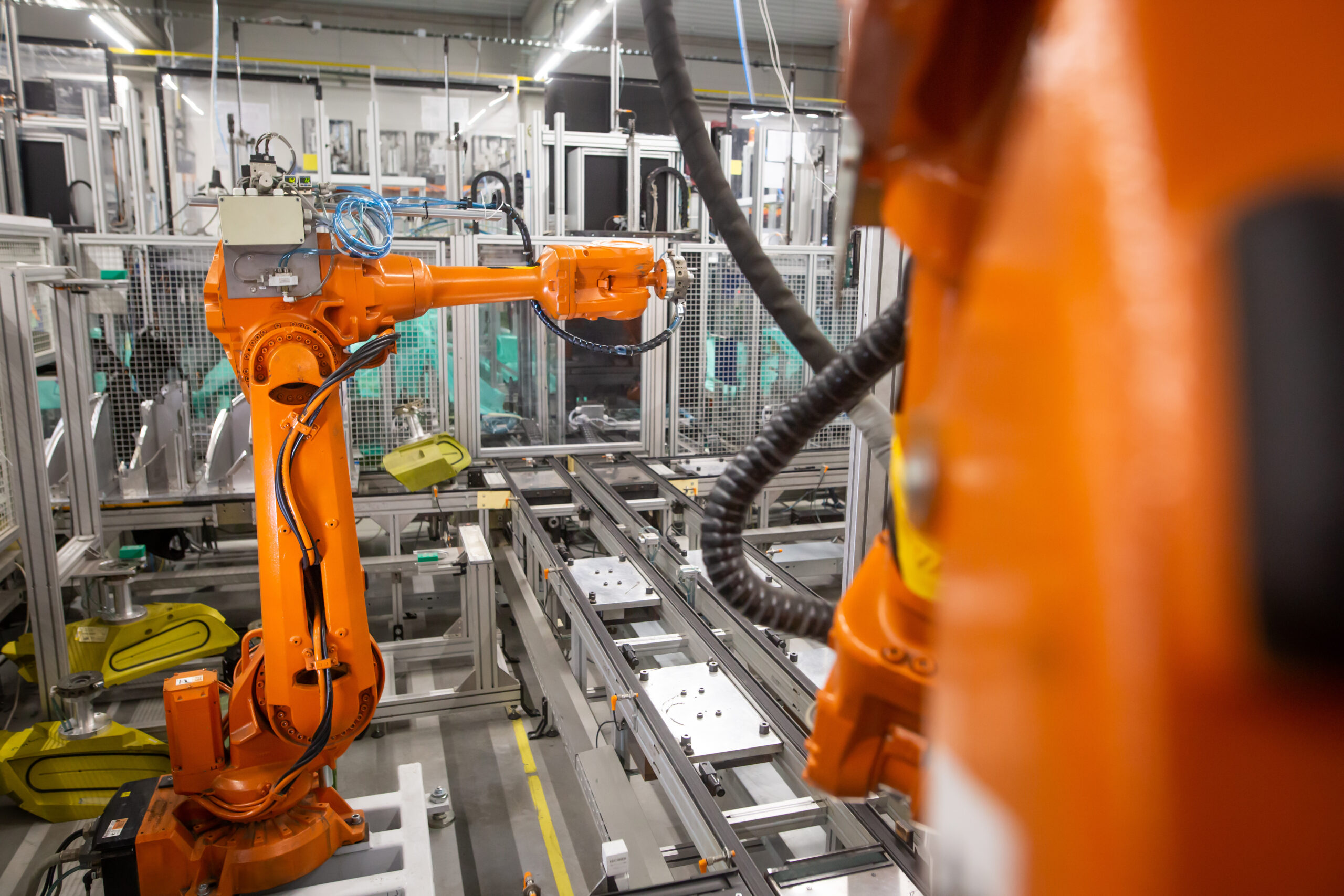

Situation A Fortune 50 company needed to create a custom automated production system for consumer vapor products. Action Our team of engineers programmed a complex assembly system which included 18 robots, 9 Cognex vision inspections, RFID reading, vacuum pick and

Unplanned downtime can be a killer for manufacturing costs. Predictive maintenance helps eliminate unplanned downtime by allowing manufacturers to be proactive and use data to guide their work. This article in IndustryWeek provides a good overview of predictive maintenance and

Allen-Bradley Ultra3000 Servo Drives were discontinued by Rockwell at the end of 2016. The Ultra3000 has been a valuable work horse for Rockwell Automation customers. These drives were able to do standalone indexing as well as ride on both DeviceNet and

There is one refrain we hear more often from our peers and customers than any other: there is a shortage of people with the skills required to work at manufacturers and control system integrators. There are many causes for this

Ransomware and cyber attacks at manufacturers is becoming increasingly common, disrupting operations and causing millions of dollars worth of damages. Consumer Products company Reckitt Bensicker was recently the victim of one such attack that impacted the company’s 60 factories. What

Situation A Mark Cuban backed startup company with an innovative concept to automate cocktail mixing approached Automation NTH with a desire to scale up its production, but didn’t know where to start. Action We interviewed the customer to understand their

©2023 Automationnth – All Rights Reserved | Privacy Policy